Company Information

Ask for more detail from the seller

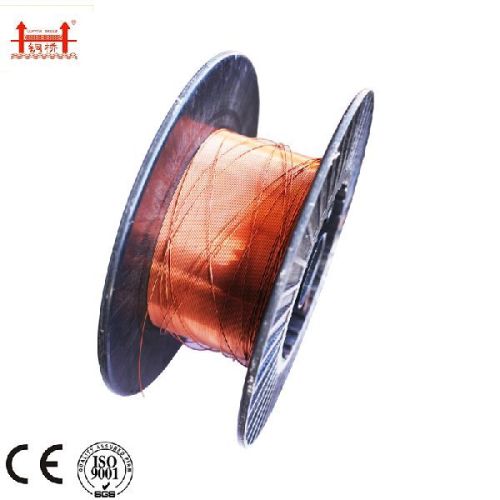

Contact Supplier0.8mm 1.0mm 1.2mm Copper Coated CO2 Welding Wire CHS 49-1 is a copper-coated solid welding wire, it can be welded with CO2 as the shielding gas, with excellent welding technological properties, stable arc, less spatter, a higher pores resistance property and a higher deposition efficiency. It is suitable for all position. Application: The welding wire is used for welding structures of low carbon structural steel and Iow alloy steel. Such as ships, bridges, heavy-duty machines, boilers and pressure vessels, etc. Welding wire Chemical Composition % LY GB C Mn Si S P Cu H08Mn2SiA ER49-1 ≤0.11 1.8-2.10 0.65-0.95 ≤0.03 ≤0.03 ≤0.35 ER50-4 ER50-4 AWS ER70S-4 0.07-0.15 1.00-1.50 0.65-0.85 ≤0.035 ≤0.025 ≤0.35 ER50-6 ER50-6 AWS ER70S-6 Jis YGW12 0.06-0.15 1.40-1.85 0.80-1.15 ≤0.035 ≤0.025 ≤0.35 ER50-7 ER50-7 AWS ER70S-7 0.07-0.15 1.50-2.00 0.50-0.80 ≤0.035 ≤0.025 ≤0.35 Mechanical properties of deposited metal LY GB Tensile strength Mpa Yield strength Mpa Extension rate % temperature J H08Mn2SiA ER49-1 ≥490 ≥372 ≥20 Normal ≥47 ER50-4 ER50-4 AWS ER70S-4 ≥500 ≥420 ≥22 ER50-6 ER50-6 AWS ER70S-6 Jis YGW12 ≥500 ≥420 ≥22 -29°C ≥27 ER50-7 ER50-7 AWS ER70S-7 ≥500 ≥420 ≥22 -29°C ≥27 Specications and Weight of Reference Electric Currentd Dia mm 0.6 0.8 0.9 1.0 1.2 1.6 Currentd 25-110 40-140 50-200 70-250 80-350 170-450 Kg 1/5/10 15/20 15/20 15/20 20 20