Company Information

Ask for more detail from the seller

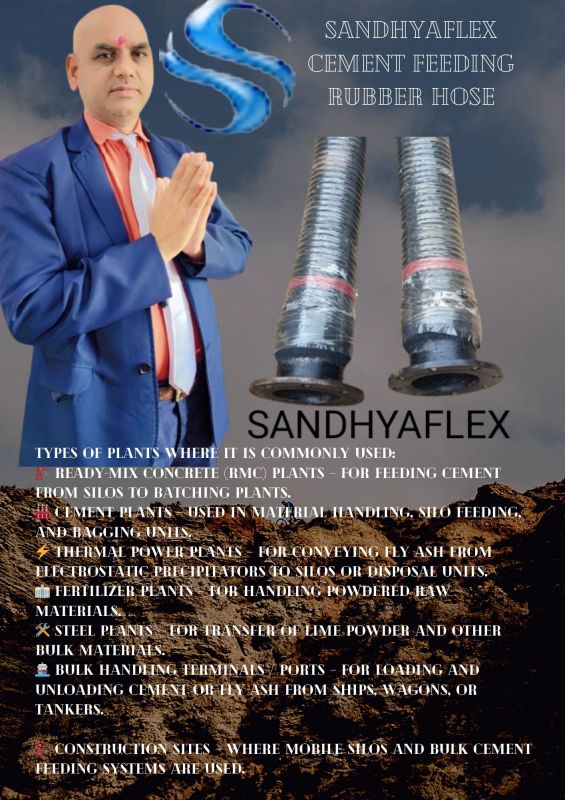

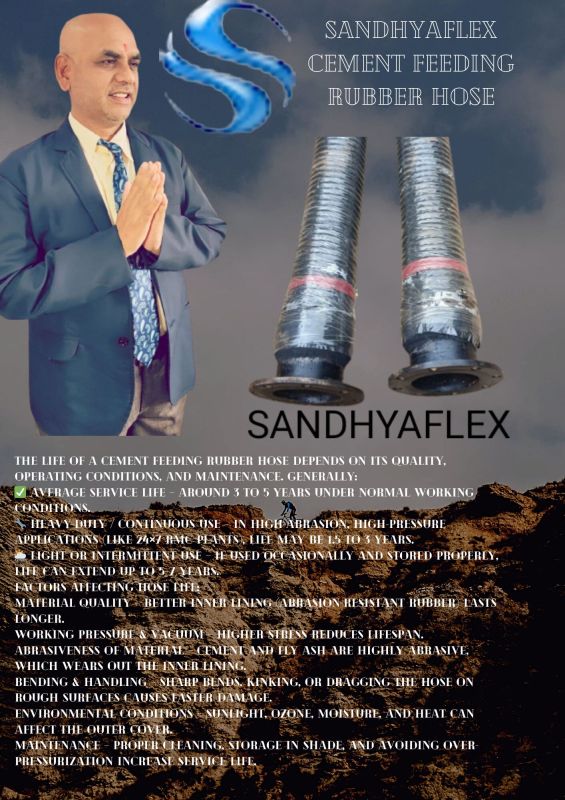

Contact SupplierA Cement Feeding Rubber Hose is a specialized industrial hose used mainly in construction, cement plants, and material handling systems for the safe and efficient transfer of cement, fly ash, dry plaster, powders, and other abrasive materials under pressure or pneumatic systems.

Here’s a detailed overview:

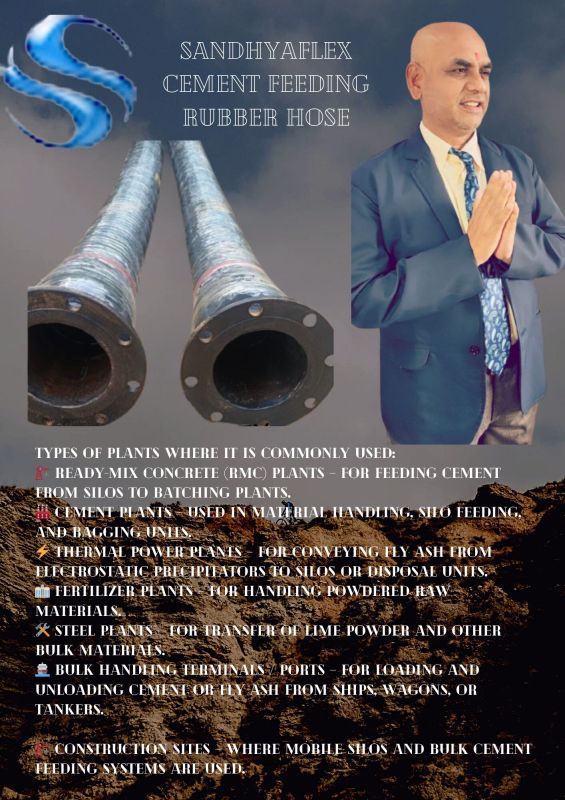

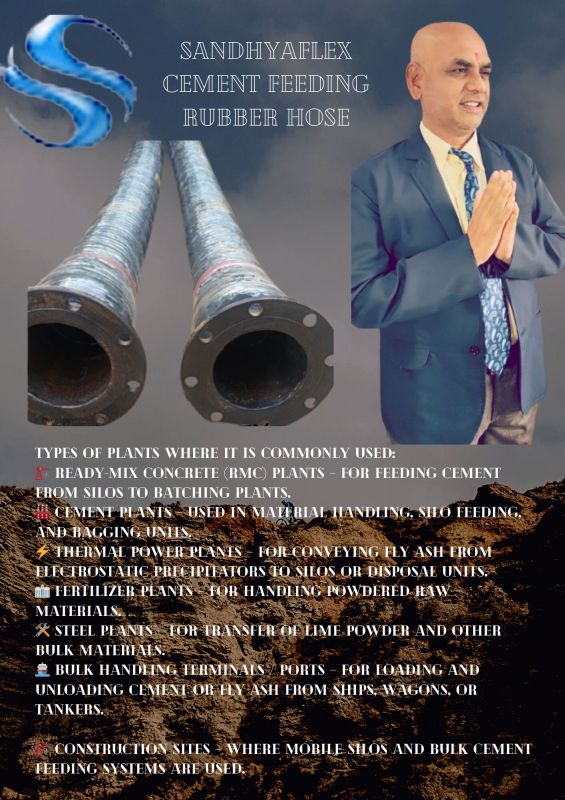

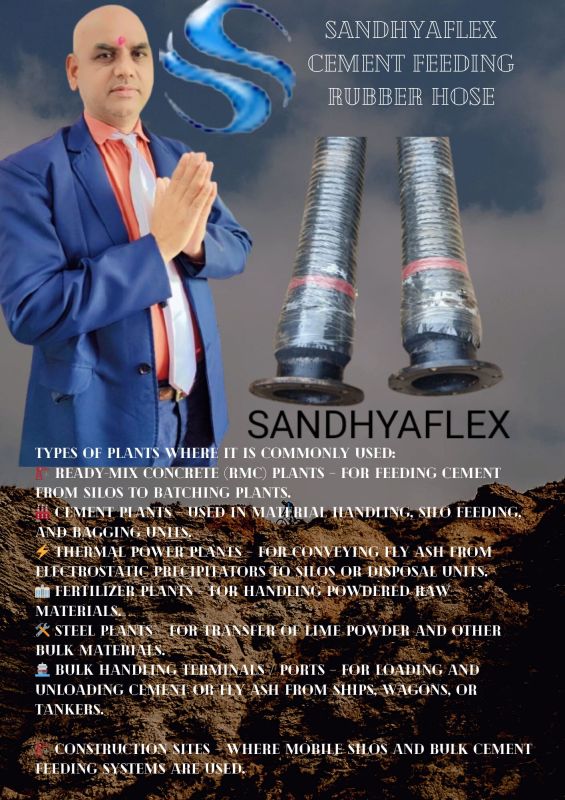

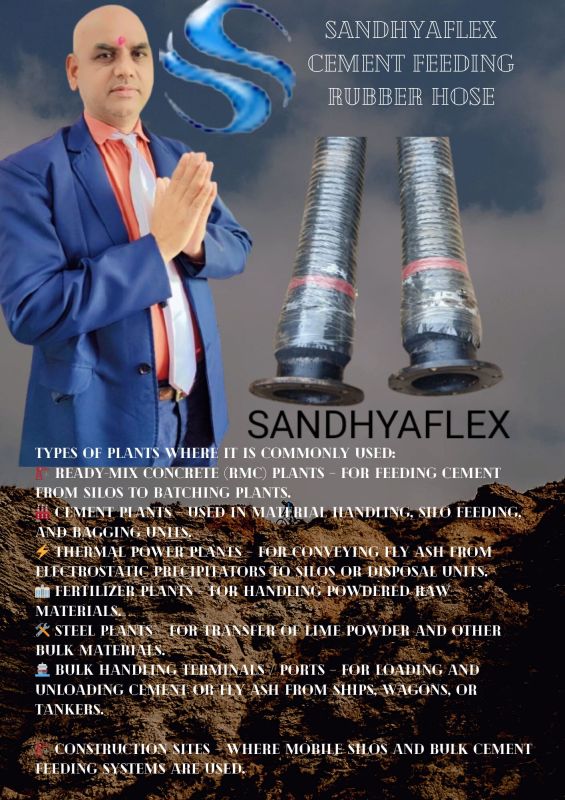

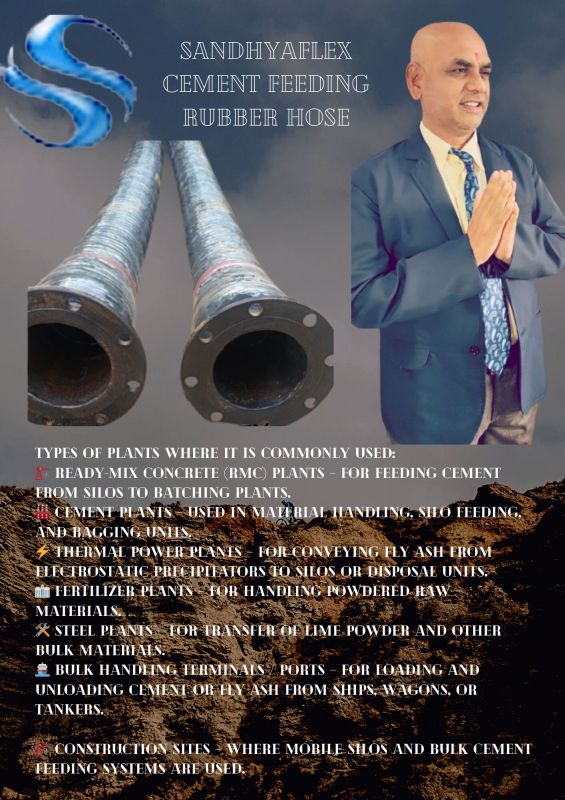

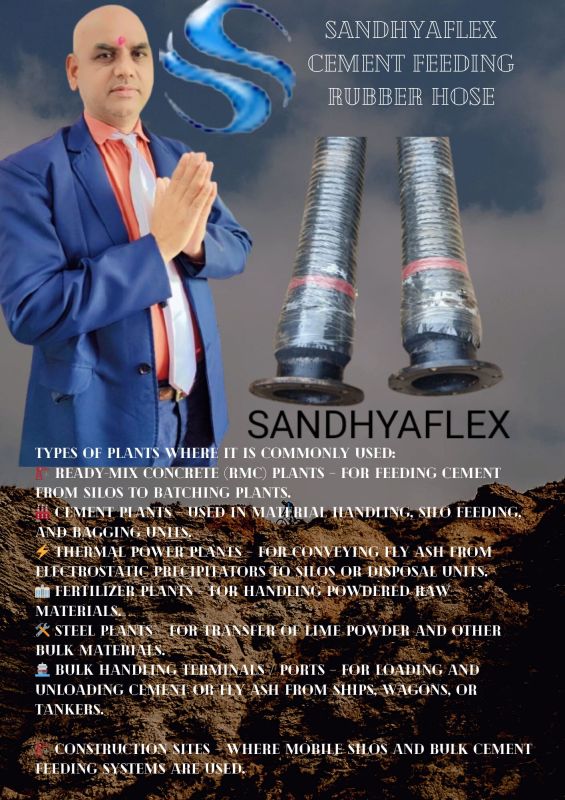

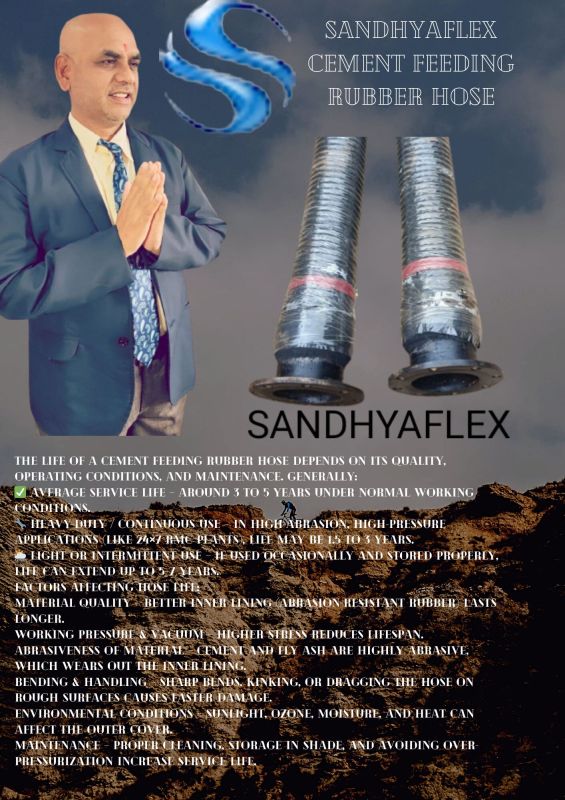

🔹 Product DescriptionName: Cement Feeding Rubber Hose

Brand: Often available as Sandhyaflex Cement Feeding Rubber Hose

Type: Heavy-duty, abrasion-resistant rubber hose

Structure: Typically made of synthetic rubber with reinforcement

Tube (Inner Layer):

Made from smooth synthetic rubber.

Resistant to abrasion and wear caused by dry cement and fine particles.

Reinforcement:

High tensile synthetic textile cords and/or steel wire helix.

Provides strength to withstand working pressure.

Cover (Outer Layer):

Weather-resistant, abrasion-resistant rubber.

Protects against external damage, UV, and rough handling.

High abrasion resistance (handles cement, fly ash, powders).

Flexibility for easy handling during material transfer.

Withstands high working pressure used in pneumatic conveying.

Durable under rough construction site use.

Available in sizes from 50mm NB to 200mm NB (custom as per requirement).

Transfer of cement, dry plaster, powders, fly ash in construction & RMC plants.

Suction & discharge of dry bulk materials in silos and tankers.

Widely used in cement factories, construction sites, bulk carriers.

Working Pressure: Usually up to 10–15 Bar (varies by design).

Burst Pressure: Generally 3 times the working pressure.

Temperature Range: –30°C to +80°C (depends on grade).

👉 Would you like me to also prepare a comparison table of Cement Feeding Rubber Hose vs. normal Rubber Hose, so you can show customers the advantages clearly?