Company Information

Ask for more detail from the seller

Contact SupplierOutline

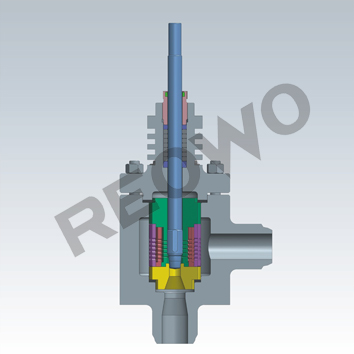

The 10S Series unbalanced multi-stage pressure drop control valve is suitable for applications with high differential pressure and applications t hat produce flash evaporation and cavitation. According to the requirements in different service conditions, it is designed with various multi-hole cages that form a multi-stage pressure drop that form a multi-stage pressure drop trim, so that the internal energy of high trim, so that the internal energy of high speed media is consumed and flow velocity is reduced from the time when the fluids contact the first cage. As it is composed of various cages, the pressure is gradually reduced so that the medium pressure is always above the saturated vapor pressure, and the occurrence of flash evaporation and caitation is eliminated. The standard configuration is the unbalanced single- seat plug and the plug and seat are subjected to hardening treatment to prolong the service life of the trim. The valves of large sizes can be designed with the balanced single-seat plug structure.

Parameters of control valves

DN 15~450mm

PN Class150~2500

Applicable temperature range -196℃- 570℃

Trim features sleeve guided unbalanced trim structure, combination of multi-hole cages

Body type straight-through type, angle type.

Bonnet type standard type, heat dissipation type, cryogenic type, bellows

Flow characteristic equal percentage, linear, quick open

Shut-off class ASME B16.104 V (standard metal seat)

ASME B16.104 V I (shut-off soft seat)

Pipe connection type flange type, butt welding type

Actuator type pneumatic diaphragm actuator

pneumatic piston actuator

Electric actuator