Company Information

Ask for more detail from the seller

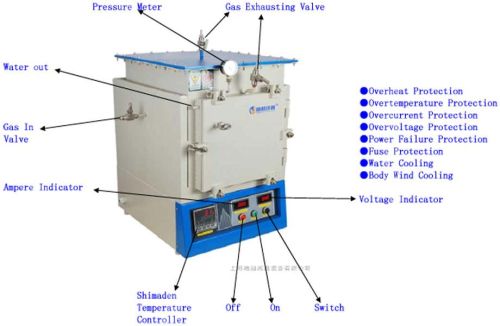

Contact SupplierWe offer 1100� muffle atmosphere furnace.

application

used widely into the primary trial of the laboratory, enterprise and scientific research unit, is also the ideal apparatus to do atmosphere sintering, the reducing atmosphere (the reducing inert atmosphere, hydrogen and nitrogen mixed atmosphere etc.).

features

the furnace uses resistance wire as the heating element, designed with the double-shell structure and 50 steps programmable thermal controlling system, controlled silicon controls, phase-shift trigger. The chamber adopts 1600 type alumina polycrystal fiber as its material, there is wind cooling system between the double shells of furnace, which make the quick rise of temperature, the whole seal design of outer shell, its cover is sealed with silica gel, furnace door uses silica gel gasket possessing the water cooling system, the gas goes into furnace chamber via the flowmeter, the gas outlet has the burning nozzle which goes into or out by hydrogen, argon, nitrogen, oxygen etc. The furnace enjoys these advantages such as: he temperature uniformity in furnace chamber, the lower surface temperature, the quick speed of temperature rise, saving energy etc. It is the ideal apparatus for university, scientific research institutes and enterprises to do atmosphere protective sintering and atmosphere reducing.

optional accessories

computer control, rs485 or rs232 interface, the recorder without paper, tester of oxygen content , atmosphere control (floating flowmeter, mass flowmeter); vacuum pump, air feed ( mixing gas ) system.

main technical parameters:

model

chamber size (lxwxh) (mm)

power

(kw)

max. Temp. (�)

rated temp.

(�)

heating element

voltage(v)

heating rate(�/min)

hmx1100-20

200x200x200

2

1100

1000

resistance wire

220

�20

hmx1100-30

300x200x200

4

1100

1000

resistance wire

220

�20

hmx1100-40

400x300x300

12

1100

1000

resistance wire

380

�20

hmx1100-50

500x300x300

15

1100

1000

resistance wire

380

�20