Listing ID #6322018

Company Information

Ask for more detail from the seller

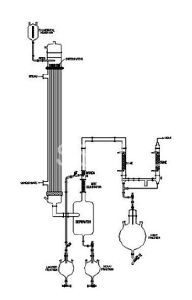

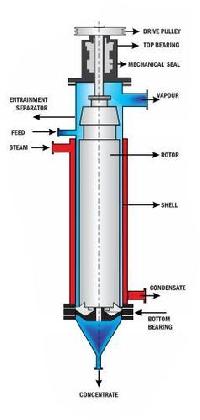

Contact SupplierA Falling film evaporator is an industrial device to concentrate solutions, especially with heat-sensitive components. The evaporator is a special type of heat exchanger. In Falling film evaporators, the liquid film falls by gravity in the vertical evaporation surface that is inside the tube or plate, while the heat is transferred through the walls by the condensing steam. It is used for the concentration of yeast extract, manufacturing of gelatin, extracts of tea and coffee. It is used to separate volatile and nonvolatile materials when the feed is low viscosity. We are manufacturer of Falling Film Evaporator for Herbal Extraction Plant and Phytochemical Plant.

Able Engineering‘s Falling film evaporators gently treat your temperature-sensitive products in a gentle way: The use of vacuum and the short residence time along the heated surface are two essential parameters in preventing secondary reactions and preserving organoleptic properties. Able Engineering’s Falling Film Evaporators specifically suit to process your products with low viscosity and a low tendency for fouling. It consists of a tube bundle crowned by a proprietary liquid distribution device that ensures an efficient and uniform distribution of the liquid to all the tubes. Your product flows as a continuous film along the tube length, driven by gravity.

What is a Falling Film Evaporator

It is an industrial device to concentrate solutions, especially with heat-sensitive components. The evaporator is a special type of heat exchanger.

Multi-Effect Falling Film Evaporator Main features

More Application