Company Information

Ask for more detail from the seller

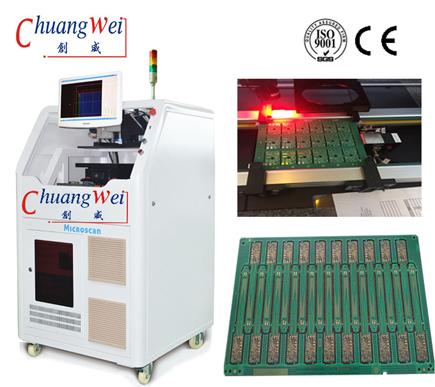

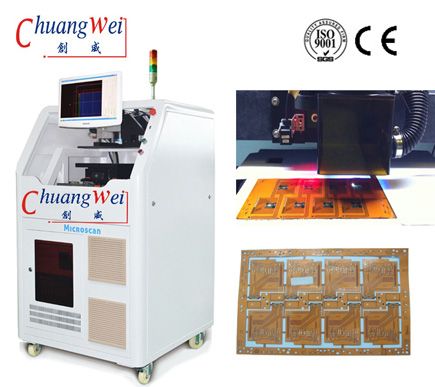

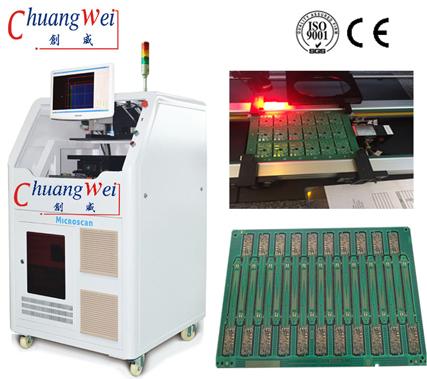

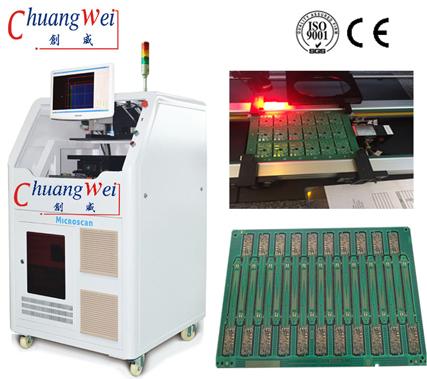

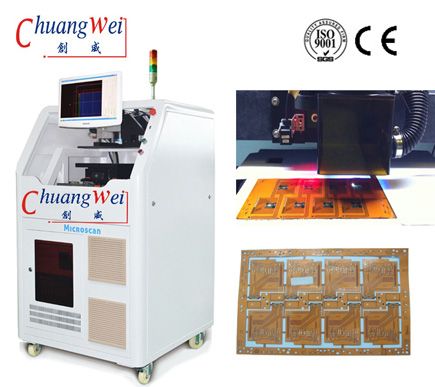

Contact SupplierChallenges of depaneling using routingdie cuttingdicing saws: · damages and fractures to substrates and circuits due to mechanical stress · damages to pcb due to accumulated debris · constant need for new bits, custom dies, and blades · lack of versatility – each new application requires ordering of custom tools, blades, and dies · not good for high precision, multi-dimensional or complicated cuts · not useful pcb depaneling singulation smaller boards lasers, on the other hand, are gaining control of the pcb depaneling singulation market due to higher precision, lower stress on the parts, and higher throughput. Laser depaneling can be applied to a variety of applications with a simple change in settings. There is no bit or blade sharpening, lead time reordering dies and parts, or cracked broken edges due to torque on the substrate. Application of lasers in pcb depaneling is dynamic and a non-contact process. Routing-pcb laser separator by using pcb depanelize,cwvc-6 application: fpc and some relative materials; fpcpcb rigid-flex pcb cutting, camera module cutting.