Company Information

Ask for more detail from the seller

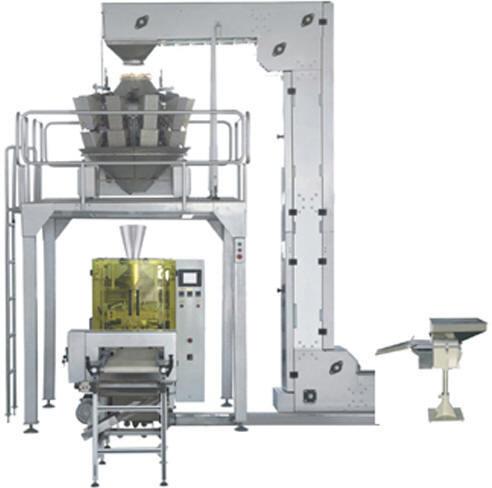

Contact SupplierWe are offering universal engineering

list of packaging machines

semi automatic machines

auger filler with electro magnetic clutch operated (for hygroscopic type powder) suitable to measure and fill powder in pre-made bags & plastic containers. All the contact parts of the machine are made of ss- 304.( can be attachable with packing machine)100 gms to 1 kg

production output: 25 to 20 dropsmin. 250 gms to 1 kg drops

model no ue1101af

volumetric cup filler (for free flow products) suitable to measure and fill powder granules in pre-made bags & plastic containers. Provided with ad. Volumetric disc. All the contact parts of the machine are made of ss- 304.( can be attachable with packing machine) filling capacity 250 to 1000 gms

production output: 20 to 25 dropsmin.

Model no ue1201vf

electronically weighing and filling machine load cell based, suitable to weighing & filling rice pulses in pre-made bags. (can be attachable with packing machine). Equipped with electronic load cell. Capacity 1-2 kgs. Accuracy : +- 1.0%

production output: 10-15 bagsmin.

Model noue1301wf