Company Information

Ask for more detail from the seller

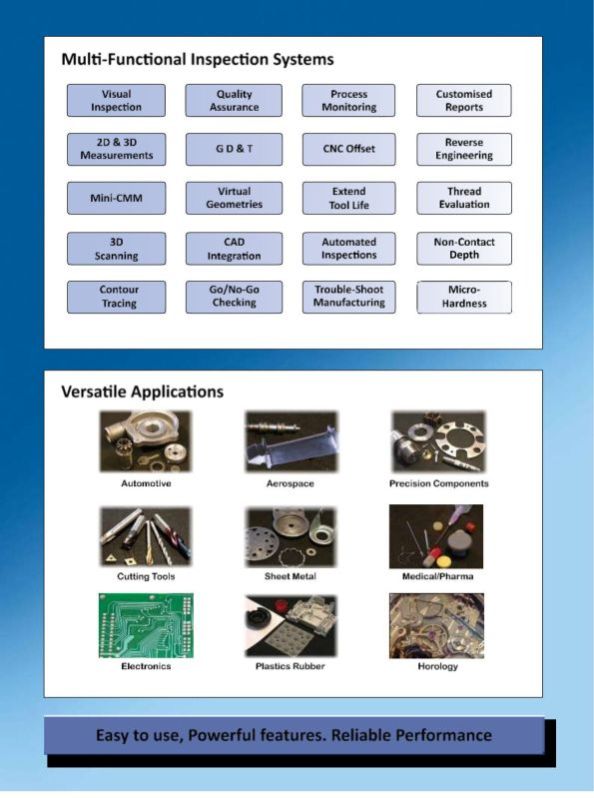

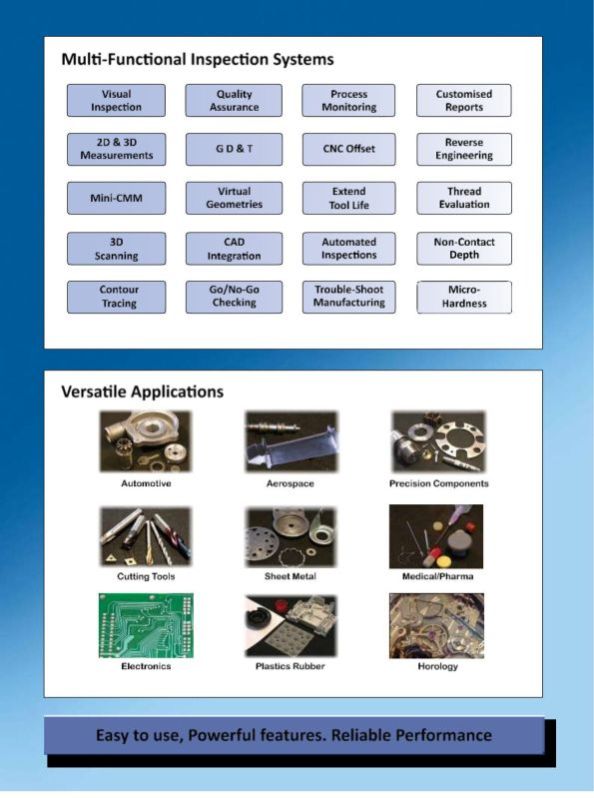

Contact SupplierQuality Inspection is an activity of checking, measuring, or testing one or more product or service characteristics and comparing the results with the specific requirements to confirm compliance. This task is executed by skilled personnel, not by production workers.

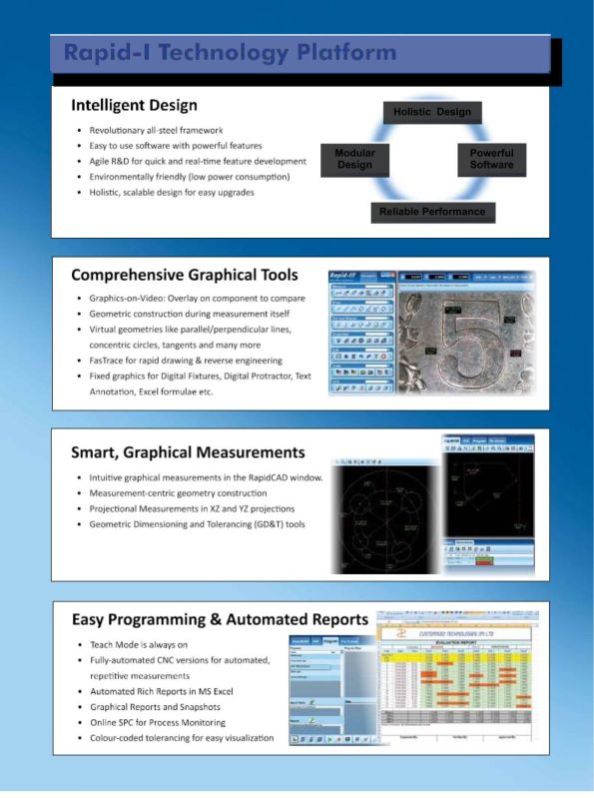

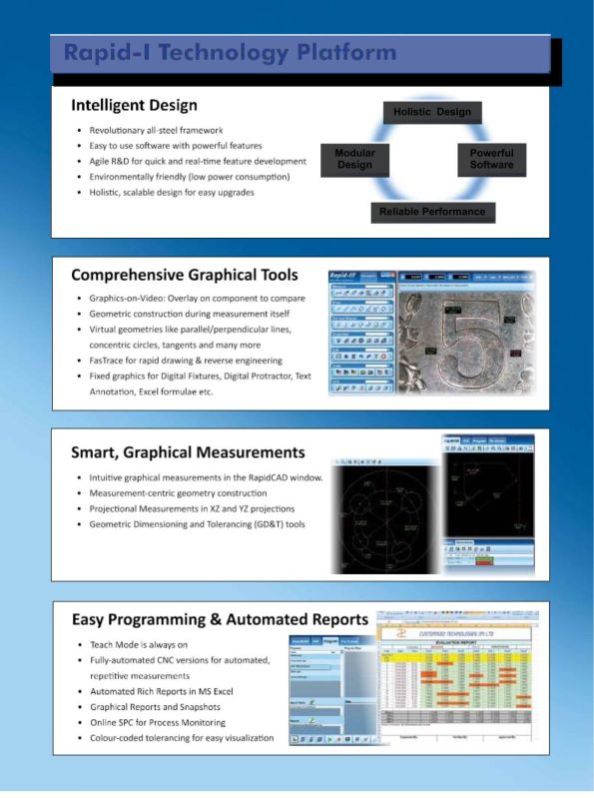

2D Inspection Using Portable CMM: Portable Coordinate Measuring Machines (CMMs) are versatile tools for performing accurate 2D inspections. Here’s how they work:

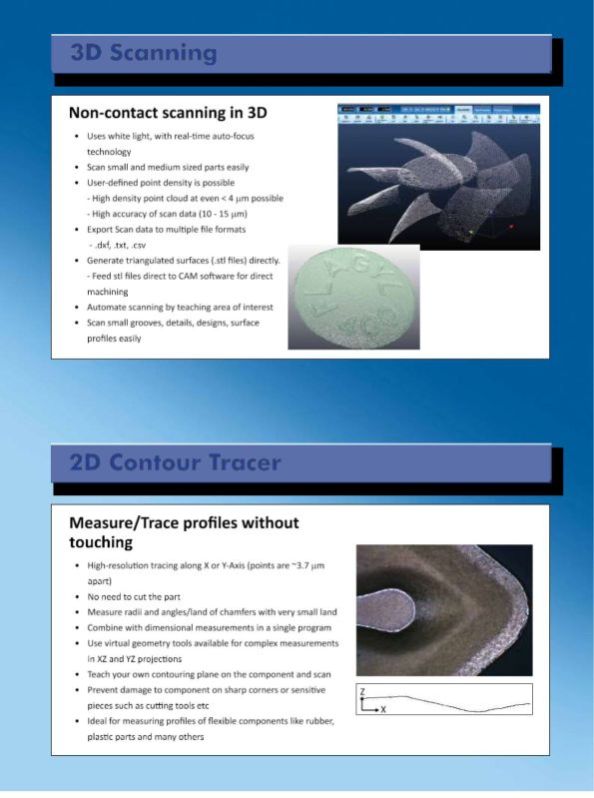

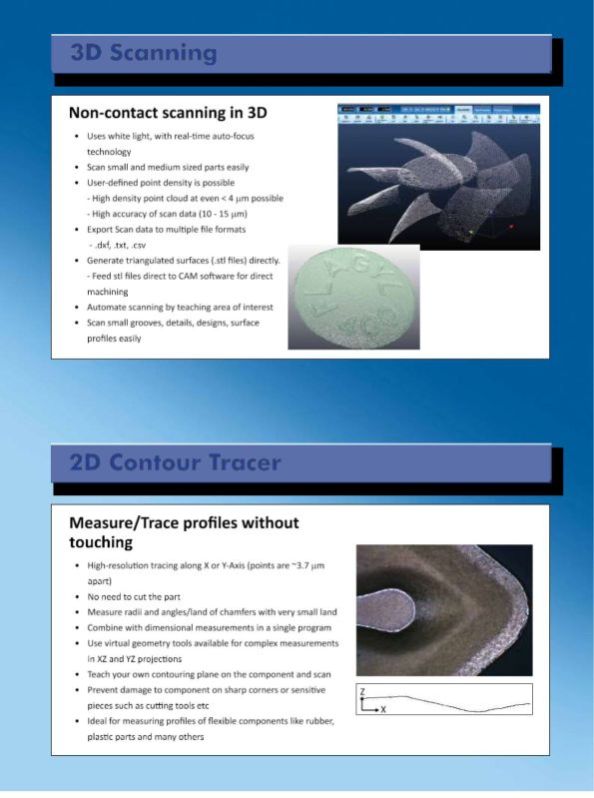

We use specialized software for Scan to CAD inspection to give our customers a complete comprehensive report on the deviation analysis.