Company Information

Ask for more detail from the seller

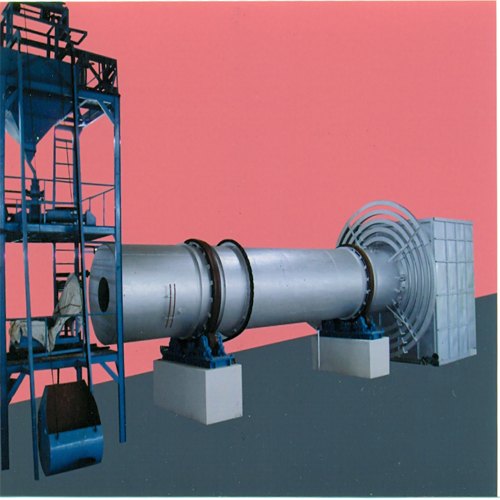

Contact SupplierThe process of activation is carried out in two stages. Firstly, the coconut shell is converted into shell charcoal by carbonization process which is usually carried out in mud pits, brick kilns and metallic portable kilns. The coconut shell charcoal is activated by reaction with steam at a temperature of 900 OC – 1100 OC under controlled atmosphere in rotary kilns. The reaction between steam and charcoal takes place at the internal surface area, creating more sites for adsorption. The temperature factor, in the process of activation is very important. Below 900 OC the reaction becomes too slow and is very uneconomical. Above 1100 OC the reaction becomes diffusion controlled and therefore takes place on the outer surface of the charcoal resulting in loss of charcoal.

In the process of activation of charcoal, the solid carbonaceous fuel is converted in to combustible gases termed as producer gas by partial combustion with limited supply of air and remaining fixed carbon being converted into Activated Carbon by steam.

The manufacture of Activated Carbon divided into three categories as