Company Information

Ask for more detail from the seller

Contact SupplierBalanced Bellows

This valve is the same as the conventional design except that a bellows has been added. When the bellows is installed, the educator tube is removed. Caution: It is important that the bonnet be vented to the atmosphere. A bellows is added to the conventional valve to deal with any of several situation.

Back pressure entering the valve through the valve outlet is excessive or variable. If back pressure fluctuates with ±10% of a nominal value, a bellows is required. If a built up back pressure exceeds 10% of the set pressure or cold differential set pressure, a bellows must be used.

If the entering fluid is slurry, highly viscous, or of a nature that it can enter the critical clearances between the guides/disc holders, protect that area with a bellows.

If the fluid being handled is corrosive to the upper works of the valve, isolate the bonnet chamber through use of a bellows. Conventional valves can be easily converted to a bellows design or vice versa through the use of retrofit kits. All valves are balanced bellows designs, meaning that they fully compensate for the effects of back pressure.

Standard safety valves are generally fitted with an easing lever, which enables the valve to be lifted manually in order to ensure that it is operational at pressures in excess of 75% of set pressure.

This is usually done as part of routine safety checks, or during maintenance to prevent seizing. The fitting of a lever is usually a requirement of national standards and insurance companies for steam and hot water applications. A standard or open lever is the simplest type of lever available. It is typically used on applications where a small amount of leakage of the fluid to the atmosphere is acceptable, such as on steam and air systems. Where it is not acceptable for the media to escape, a packed lever must be used. This uses a packed gland seal to ensure that the fluid is contained within the cap

Open Bonnet

Unless bellows or diaphragm sealing is used, process fluid will enter the spring housing (or bonnet). The amount of fluid depends on the particular design of safety valve. If emission of this fluid into the atmosphere is acceptable, the spring housing may be vented to the atmosphere – an open bonnet. This is usually advantageous when the safety valve is used on high temperature fluids or for boiler applications as, otherwise, high temperatures can relax the spring, altering the set pressure of the valve. However, using an open bonnet exposes the valve spring and internals to environmental conditions, which can lead to damage and corrosion of the spring.

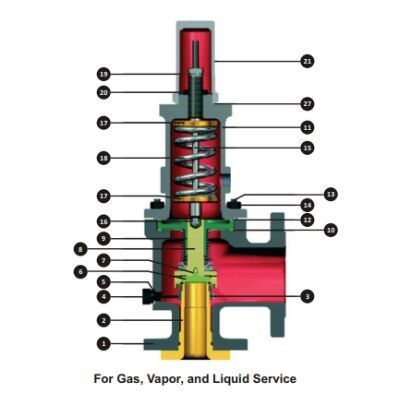

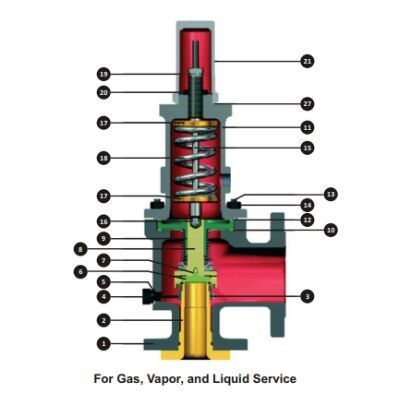

| S.No. | PART | MATERIAL |

| 1 | Body | ASTM A216 WCB/ CF8/ CF8M/CF3M |

| 2 | Nozzle | 410 SS /304 SS /316 SS /316L SS |

| 3 | Adjusting ring | 410 SS /304 SS /316 SS /316L SS |

| 4 | Adjusting ring pin | 410 SS /304 SS /316 SS /316L SS |

| 5 | Adjusting ring pin gasket | Soft iron/PTFE/Neoprene rubber/CAF |

| 6 | Disc | 410 SS /304 SS /316 SS /316L SS |

| 7 | Disc retainer | ringInconel X750 |

| 8 | Disc holder | 410 SS /304 SS /316 SS /316L SS |

| 9 | Guide | 410 SS /304 SS /316 SS /316L SS |

| 10 | Guide gasket | Soft iron/PTFE/Neoprene rubber/CAF |

| 11 | Bonnet | ASTM A216 WCB/ CF8/ CF8M/CF3M |

| 12 | Bonnet gasket | Soft iron/PTFE/Neoprene rubber/CAF |

| 13 | Stud | B7 Alloy steel |

| 14 | Fastener | B7 Alloy steel |

| 15 | Spindle | 410 SS /304 SS /316 SS /316L SS |

| 16 | Spindle retainer | Inconel X750 |

| 17 | Spring Washer | Carbon steel |

| 18 | Spring | Alloy steel, Tungsten, Spring Steel |

| 19 | Adjusting Screw | 410 SS /304 SS /316 SS /316L SS |

| 20 | Adjusting Screw locknut | 410 SS /304 SS /316 SS /316L SS |

| 21 | Screwed Cap | Carbon steel |

| 22 | Bellows | Inconel 625 LCF |

| 23 | Bellows ring & Flange | 410 SS /304 SS /316 SS /316L SS |

| 24 | Bellows Gasket | Soft iron/PTFE/Neoprene Rubber/CAF |