- Supply TypeManufacturer, Exporter, Supplier, Retailer

- Preferred Buyer Location All over the world

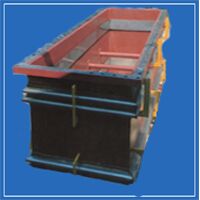

Rectangular Bellows especially used in low pressure ducting to absorb thermal expansion of duct and vibration from equipment. Rectangular Expansion Joint have a single, miter, camera and rounded corner design to absorb axial and lateral movement due to thermal expansion of system.