Company Information

Ask for more detail from the seller

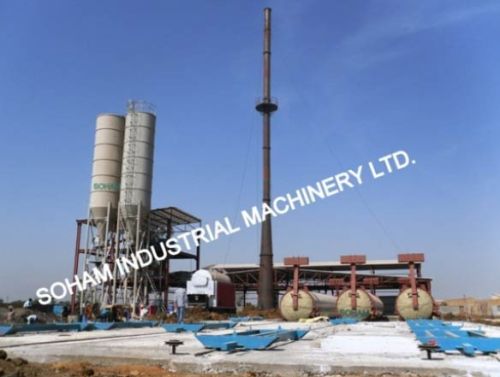

Contact SupplierWe are one of the professional Manufacturers & Suppliers of Autoclaved Aerated Concrete (AAC) Block Production Plant in India. We can supply complete set of AAC Block Production Plant with 50000, 100000, 150000m3 capacity annually (from 166 m3 to 500m3 per day). The AAC Block Production Plant offered by us includes plant design, equipments installation, technical instruction, personal training, etc., We also design and manufacture the AAC Block Production Plant as per clients' requirement. Plant design :