Company Information

Ask for more detail from the seller

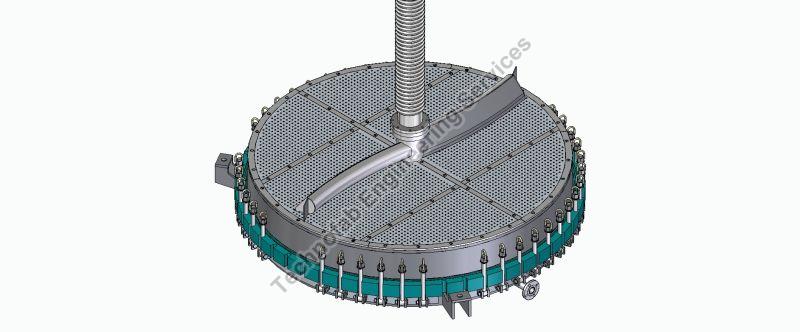

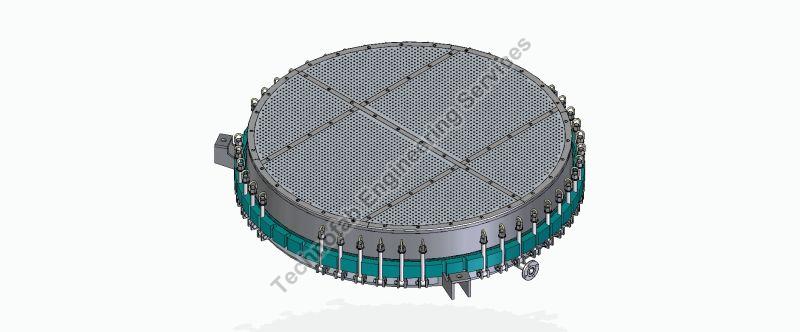

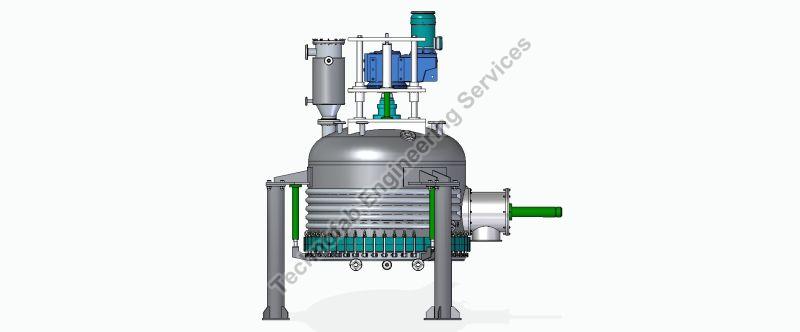

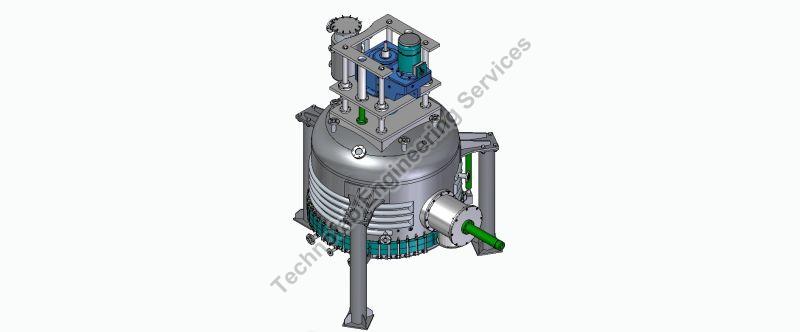

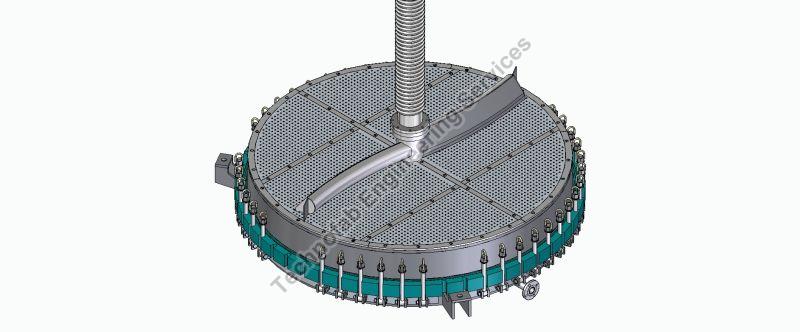

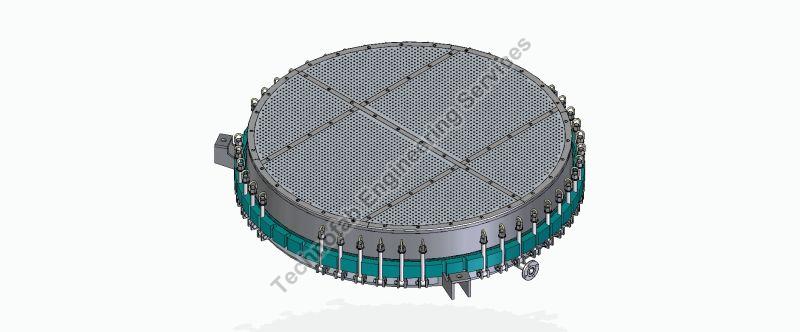

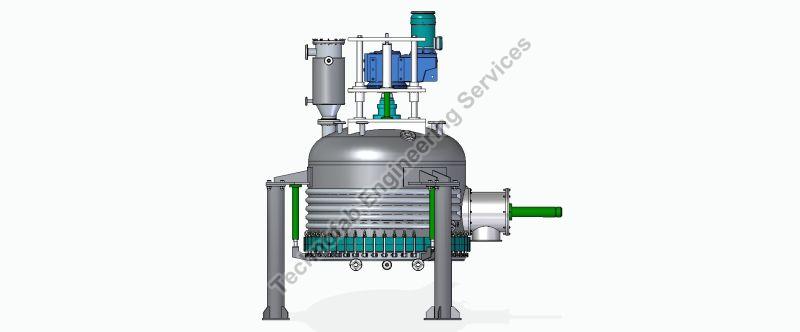

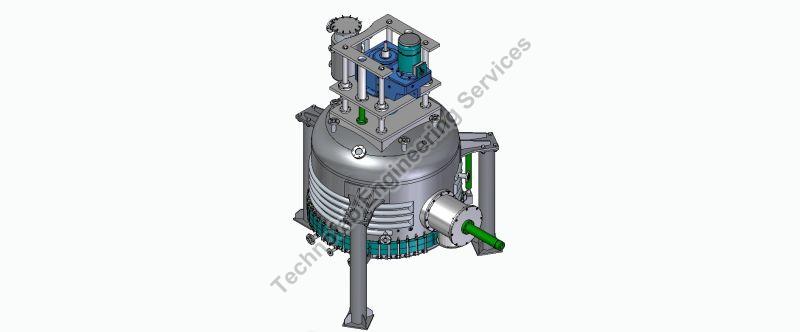

Contact SupplierAGITATED NUTSCHE FILTER DRYER (Removable Type)

Agitated Filter is a closed vessel designed to separate solid and liquid by filtration under pressure or vacuum. The closed operation ensures odorless, contamination free and nonpolluting working conditions maintaining product purity and hygiene. The advanced technology of agitation and hydraulics used in the equipment makes it versatile and user friendly. The resulting wet cake can be re-slurried and washed thoroughly with water or solvents.

Wash liquid quantity can be controlled and recycled, reducing effluent load. The discharge of wet cake is automatic. If the process demands filtration in chilled or hot condition, it is also possible. Drying of wet cake is also possible when drying features are incorporated.

Advantages

Applications : The filter dryer has wide field of applications in chemical, pharmaceutical, Agro chemicals, fine chemicals, and food industries.