Listing ID #5049535

Company Information

Ask for more detail from the seller

Contact SupplierCooling Is EQUALY Important as Heating

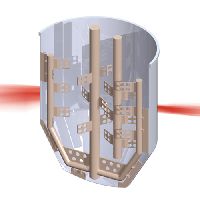

Submersible Agitator is a key equipment for Quenchant Tank Agitation in Heat Treatment process. The Airless agitation with 0.5-2.0 m/sec. velocity resulting in 8000 C/min hot job cooling rate achieves the required properties. The Submersible Agitators are any time removable equipment, not only agitates the quenchant but offers high thrust on hot jobs, due to which vapour blanketing is instantly broken (or do not allow) and heat is dissipated at tremendous rate. It is used for Water, Water Polymer and Oil Quenching Tanks very effectively.

The performance parameters of the submersible agitators are shown in the following table with the rated voltage of 415V and the frequency of 50Hz. However special agitators with 380V ~ 60 Hz or other supply conditions are available on request.

Quenchant- Water, Oil, Polymer.

Cooling Rates- 800 c/min.

Velocity- 0.6 m/sec.