Company Information

Ask for more detail from the seller

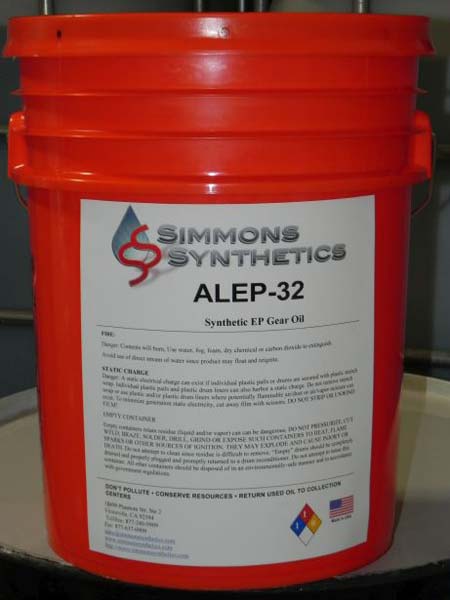

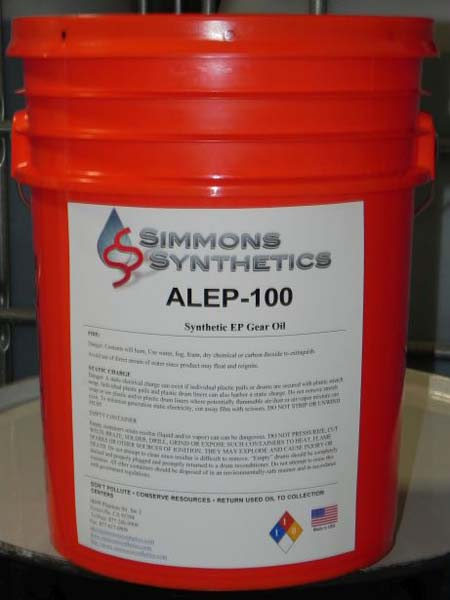

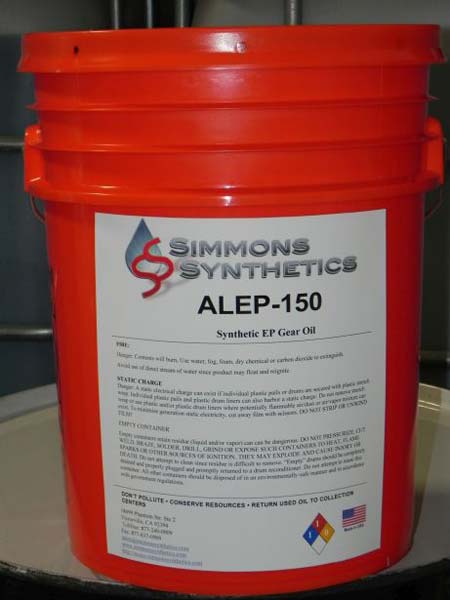

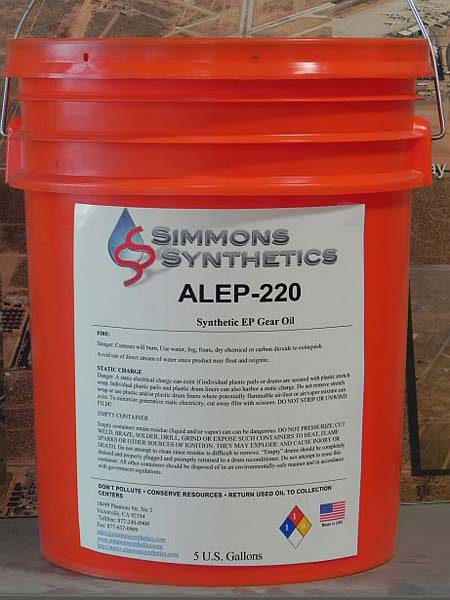

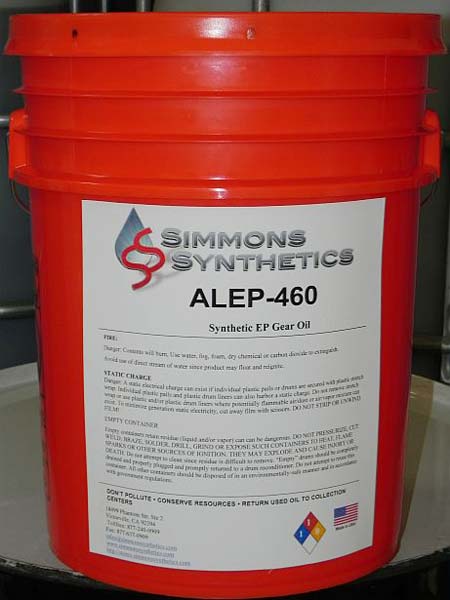

Contact SupplierThe ALEP Synthetic EP Gear Oil that we offer is comprehensively used for enclosed gearing as well as plain and rolling element bearings. It is free from all sorts of impurities and can be acquired from us at the cost-effective prices.

Applications : ALEP-1000 Series Synthetic EP gear oils are recommended for use in all types of enclosed gearing as well as plain and rolling element bearings. These oils are ideal for heavily loaded low speed gears and bearings where boundary or elasto-hydrodynamic lubrication (EHL) conditions exist, such as in mine hoist gear reducers. They are particularly recommended for gearboxes which operate under excessively high temperatures where good quality conventional oils rapidly oxidize. ALEP-1000 Series gear oils may also be used in certain open gear applications, but it is recommended that AIP lubrication engineers be consulted to select the most effective method of application.

| SO Viscosity Grade | 68 | 100 | 150 | 220 | 320 |

| AGMA Grade | 2EP | 3EP | 4EP | 5EP | 6EP |

| API gravity (ASTM D 1298) | 30.3 | 29.1 | 28.1 | 27 | 26 |

| Specific Gravity @ 60/60oF (ASTM D 1298) | 0.85 | 0.85 | 0.86 | 0.86 | 0.87 |

| Density, lbs/gal (ASTM D 1298) | 7.31 | 7.35 | 7.38 | 7.43 | 7.48 |

| Viscosity cSt @ 40°C (ASTM D-445) | 68 | 100 | 150 | 220 | 320 |

| Viscosity index (ASTM D 2270) | 95 | 95 | 95 | 95 | 95 |

| Pour point of (oC) (ASTM D-97), | -70 (-57) | -70 (-57) | -60 (-51) | -45 (-43) | -40 (-40) |

| Flash point of (oC) (ASTM D-92), | 445 (230) | 445 (230) | 445 (230) | 440 (227) | 435(224) |

| Copper corrosion strip rating (ASTM D-130) (3 Hours @ 212 F) | 1a | 1a | 1a | 1a | 1a |

| Rust Test | Pass | Pass | Pass | Pass | Pass |

| Four ball wear scar diameter, mm (ASTM D-2266) (1 Hour/75 C/1200 rpm/40 kg) | 0.3 | 0.3 | 0.39 | 0.34 | 0.3 |

| ISO viscosity grade | 460 | 680 | 1000 |

| AGMA grade | 7EP | 8EP | 9EP |

| API gravity (ASTM D 1298) | 25.3 | 25.1 | 26.2 |

| Specific gravity @ 60/60oF (ASTM D 1298) | 0.89 | 0.89 | 0.89 |

| Density, lbs/gal (ASTM D 1298) | 7.53 | 7.64 | 7.6 |

| Viscosity cSt @ 40°C (ASTM D-445) Viscosity cSt @ 100°C (ASTM D-445) | 460 37.4 | 680 49.6 | 1000 66.2 |

| Viscosity index (ASTM D 2270) | 130 | 134 | 135 |

| Pour point oF (oC) (ASTM D-97), | -35(-37) | -30 (-34) | -20 (-28) |

| Flash point oF (oC) (ASTM D-92), | 435 (224) | 416 (210) | 400 (204) |

| Copper corrosion strip rating (ASTM D-130) (3 Hours @ 212 F) | 1a | 1a | 1a |

| Rust Test | Pass | Pass | Pass |

| Four ball wear scar diameter, mm (ASTM D-2266) (1 Hour/75 C/1200 rpm/40 kg) | 0.3 | 0.3 | 0.3 |