Listing ID #4249404

Company Information

Ask for more detail from the seller

Contact SupplierThis alloy coating consists of 55% Aluminum and 43% Zinc and the balance contains majorly Silicon around 1.5% to affect excellent adhesion to the steel substrate. The metallic coating which is applied using a continuous hot-dip coating process, combines the galvanic corrosion protection of zinc with the barrier protection of aluminum. Aluzinc also displays excellent heat reflection properties, similar to aluminized steels and is more resistant to higher temperatures than hot-dip steel. It will maintain its bright appearance and reflectivity in prolonged exposures at temperatures of 320°C and is not heavily oxidized by continuous exposure to temperatures of upto 650°C. These high temperature oxidation and heat resistance attributes of ALUZINC enable the potential applications to be expanded beyond the traditional metal building market. In particular, Automotive exhaust systems, Furnace and Ovan hardware and white goods that require heat resistance (ovens, cookers, etc.) also used for Roofing and cladding, Pre-painted sheets, Air conditions, Refrigerators & Ductings etc. are potential applications of ALUZINC.

Basic differenc in production of Aluzinc against GalvanizeThe most significant difference in process is the composition of the coating bath; the bath for 55% AlSi-Zi coated sheet production is comprised of a 55% AlSi-Zn coated alloy rather than near pure zinc for Galvanized sheets. The 55% AlSi-Zn coated bath is operated at a higher temperature (600°C 0r 1120°F) than the zinc bath used for galvanizing which is operated at about 450°C (840°F). The higher temperature for 55% AlSi-Zn coated is required because of the higher melting point of the 55% AlSi-Zn coating alloy. The melting point of the 55% AlSi-Zn coating alloy is about 580°C (1180°F) while that of the zinc coating is about 417°C (780°F) . Because of the higher bath temperature and the increased corrosiveness of the aluminum rich alloy, the 55% AlSi-Zn coated pot is lined with a special refractory and is induction fired. The general galvanizing principle of the strip heating the bath metal does not apply to 55% AlSi-Zn coated where the strip entering the bath considerably cooler than the bath (depending on base quality). Much of the bath’s heat is derived from the operation of the inductors.

Prior to the strip entering the coating bath the hydrogen content of the protective atmosphere is increased for 55% AlSi-Zn coated compared to galvanized to provide maximum protection for the strip and to minimize oxidation of the bath surface.

After coating in the ‘upleg’ as the strip rises in the cooling tower, air is blown onto the surface to cool the coating at a specified rate for generating the required coating microstructure for optimum corrosion resistance also fast cooling arrangement, resin coater, induction Furnace for resin coater.

The coating has unique microstructure consisting of two layers, an aluminum-zinc overaly coating and an iron-containing inter-metallic or alloy layer. The alloy layer forms at the interface between the coating and the steel substrate and is very thin. The thickness of the alloy layer is minimized by the addition of silicon to the coating alloy. Varying amounts of aluminum, iron, zinc and silicon are contained in various phases of this layer. The overaly coating is composed of two main phases, an aluminum-rich dendritic phase and a zinc-rich interdendritic phase. The aluminum rich phase comprises about 80% of the coating volume, while the zinc-rich phase comprises about 19% of its volume the remaining 1% is taken up by the silicon particles. The unique microstructure combines the galvanic or sacrificial protection of zinc coatings with the barrier protection of aluminum (long tem protection into one product 55% Al-Zn coated sheet is produced in a variety of strength levels, from deep drawing to full hard.

| Aluzinc / Galvalume | Thickness (mm) | Width (mm) |

| Coils & Sheets | 0.14 to 1.50 mm | Upto 1250 mm Slit coil - ≥100 mm |

|---|---|---|

| Alu-Zinc Coating | AZ-70 / AZ-100 / AZ-150 / AZ-165 Or As per mutually agreed | |

| Grades | Gr 50/ Gr 80/CS types (A, B ) | |

| Standards | ASTM A 792/A 792M En 10326/En 10327, AS 1397, JIS G 3321 | |

| Yield Strength Tensile Strength In Mpa | 340 min for Gr 50 & 550 min for Gr 80 410 min for Gr 50 & 570 min for Gr 80 | |

| Micro Structure design | Its structure consists of two layers of Al-Zn overlay coat and Fe containing intermetallic / alloy layer. Al gives barrier protection and Zn gives sacrificial Galvanic protection to the steel substrate | |

| Resistance to corrosion -Salt spray life Min Hrs (ASTM B 117) | 1000 HRS, corrosion 5 % (max) for Acrylic coated | |

| Heat resistance and heat reflectivity properties. | Due to bright surface & fine spangles, excellent heat reflectivity up to 315 c, & due to high Aluminium content, Galume has heat (oxidizing) resistance up to > 320 c without discoloration and without impairment of its alloy coating. | |

| Surface | Skinpassed / non-skinpassed / tension leveled / regular & spangle | |

| Coil ID | 508 mm | |

| Coil Packaging | • First Layer (inner most) - Paper Packing (VCI). • Second layer - LDPE (polythene) sheet. • Third Layer - HDPE with woven fabric. • Fourth layer (outer most)- G.I Metallic sheet • Side disc made of G.I Metallic sheet • Metallic ID edge protector ring made of HR strip. • G.I Metallic sheet Corrugated OD ring. • Packing strip : Circumference three strips and longitudinal six strips. • Identification Stickers Sea-worthy Export Packaging sequence : | |

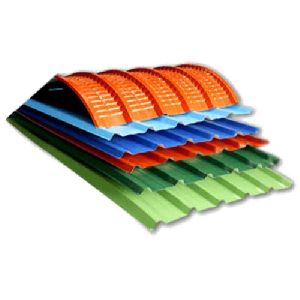

| Application | Roofing, Steel framing, false ceilings, sandwich panels, ducting, decking, purlin, Refrigerators, deep freezers, washing machines, air coolers, Auto internal components, bus bodies, Office equipments, Grain silos, drum & barrels, Crash guards / hand rails, etc. |