Listing ID #1721532

Company Information

Ask for more detail from the seller

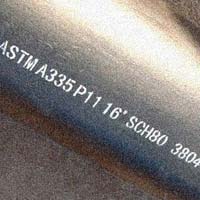

Contact SupplierOur company is counted among the eminent Manufacturers, Exporters and Suppliers of ASTM A335 P91 Alloy Steel Pipes. We make use of excellent quality steel to manufacture the pipes, which conforms to chemical composition, tensile property, and hardness requirements. Bulk orders of these are processed by us as per the specific requirements of the buyers.

Details :

|

Compositions |

Data |

|---|---|

|

UNS Designation |

K91560 |

|

Carbon(max.) |

0.08-0.12 |

|

Manganese |

0.30-0.60 |

|

Phosphorus(max.) |

0.025 |

|

Silicon(max.) |

0.50 |

|

Chromium |

4.00-6.00 |

|

Molybdenum |

0.45-0.65 |

|

Other Elements |

… |

|

Properties |

Data |

|---|---|

|

Tensile strength, min, (MPa) |

415 Mpa |

|

Yield strength, min, (MPa) |

205 Mpa |

|

Elongation, min, (%), L/T |

30/20 |