Company Information

Ask for more detail from the seller

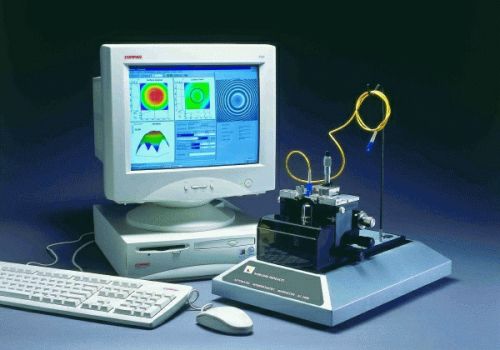

Contact SupplierThe Norland AC-3000 is a fully automated, non-contact interferometric microscope designed for

measuring the endface geometry of fiber optic surfaces such as connector assemblies, ferrules, and

optical fibers. Using a versatile inverted microscope with a built-in camera and a high-speed

computer, the AC-3000 provides immediate 3D topographical information on the surface being

inspected.

Specifically designed to measure the key parameters of PC polished connectors, the AC-3000 measures

the radius of curvature, offset of polish, undercut, or protrusion on FC, ST ® , SC, LC, and MU type

connectors. In addition, this system can measure APC, flat polished connectors, bare ferrules, cleaved

or polished fibers, and sections of multifiber connectors. The feedback from the AC-3000 provides the

user with optimum control of the production process by quickly showing any variation in the polish

quality.

The AC-3000 is a novel system that quickly switches between standard monochromatic phase shift

interferometry (PSI) or white light (broadband scanning) interferometry to handle a wide range of

surfaces. The monochromatic mode allows the system to quickly map smooth surfaces, while the

white light mode uses the latest state-of-the-art technology to measure difficult, rough surfaces and

eliminate ambiguities in step heights. This method provides the “True View” that the monochromatic

mode cannot always measure. Together, the two modes provide extra versatility for analyzing all

types of connectors, for trouble shooting or process development and for measuring fiber protrusion

(undercut or push back) up to four microns above or below the ferrule. Designed for users needing

extreme accuracy, the AC-3000 is capable of measuring fiber height to ±0.002 microns and radius of

curvature and offset of polish to ±0.10 mm and ±1.0 microns respectively. Each unit is supplied with

NIST traceable spherical calibration standards to allow the user to certify the accuracy of the

measurements. No other system provides the customer with this ultimate assurance of performance.

In less than three seconds, the advanced technology of the AC-3000 can obtain the surface topology of a

smooth connector. Coupled with a passfail function, the AC-3000 quickly converts from a valuable

research tool to an indispensable part of a modern quality control system, giving the end user full

control of fiber optic connector quality and performance. The AC-3000 with the Windows 7 operating

system is by far the easiest, most user friendly system on the market today. Simply insert a connector

into the unit, adjust the focus and analyze; the AC-3000 does the rest and results are clearly displayed

on the monitor. Use either the keyboard or the mouse to activate pull down menus, shortcut icons and

online and context-sensitive help. Fast print spooling and multiprocessing capabilities allow a hard copy

print of the information through a standard ink jet or laser printer. Data can be automatically saved,

displayed or printed in Excel for statistical analysis. In addition, custom reports can be generated for

each connector with user selectable images and measurement results (bar code labels and reports can

be printed on one page). The pressure sensitive label can be affixed to the outside of a patch cord bag.

All these data functions are accessed directly in the AC-3000 program. The unit is designed on an

extra stable, inverted microscope base for precision and ease of use. Switching from 2.5 mm connectors

to 1.25 mm connectors is accomplished in seconds with only two thumb screws. Nothing is faster or

simpler. With our new, user-friendly autolevel software, it only takes a minute to calibrate the mount

for sub-micron accuracy in offset measurements. The software also prompts the user to replace the

mount if wear becomes excessive. Our exclusive “Variable Tilt Stage” allows the instrument to be

quickly adjusted for APC measurements. The stage has continuous variable angles from 0 to 13

degrees. A NIST traceable angle standard is available that guarantees accuracy to 0.01 degrees.