Company Information

Ask for more detail from the seller

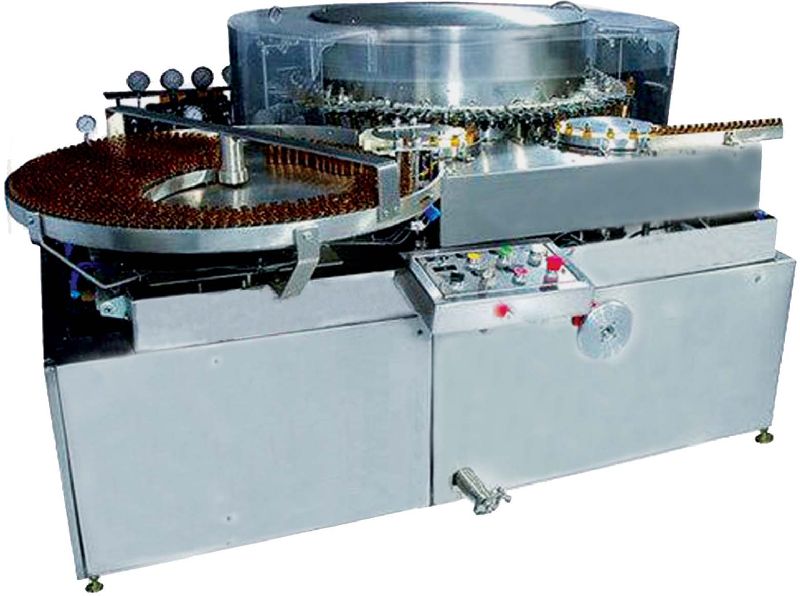

Contact Supplier| Automatic Ampoule Washing Machine is specially designed to wash Ampoule with minimum contact of machine parts with Ampoules. Machine with specially designed Gripper system holds the Ampoule from Neck and invert the Ampoule till the washing operation completed and again after washing release the Ampoule on outfeed feedworm system in vertical position ensures positive wash of Ampoules. Machine is suitable to wash 1ml to 10 ml Ampoules with the help of change parts, Ampoule feeds through feedworm to infeed Star Wheel and specially designed Gripper hold the Ampoule from neck and invert the Ampoule and move it further on rotary moving system for washing process. |

| Salient Features | ||

| Complete cGMP model | ||

| Suitable for vial sizes from 5ml to 100ml without any change parts (No change parts required) | ||

| “No Vial – No Washing” system eliminates wastage of water & air | ||

| Easy cleaning & maintaining | ||

| Machine is equipped with PLC system. | ||

| Stops supply of water & air when acrylic doors opened during operation. | ||

| Indication & alarm in PLC. | ||

| Normal water required for washing & no hot water required | ||

| When there is no vial on conveyor, it stops the water & air supply. Infeed & outfeed Turn Tables. | ||

| Imported Gear motor for main drive, unscrarnbler and scrambler | ||

| Variable A.C frequency drive for main drive, unscrambler and scrambler Acrylic cabinet for machine. | ||

| Process Operation | ||

| Form the in feed Turn Table the vials are fed into the External the Vial Washing Machine conveyors. The machine consists of two conveyors on which the vials are properly fed and transported from in feed Turn table for the washing operation. Two Operations are carried out on this machine. First the vials are washed by water jet and then dried by air jet. On the conveyor a set of spray nozzles are fitted on each on each conveyor for water Jet. One set of knife blocks are provided on each conveyor for air. The air sprayed through this knifes . The knifes are fitted in a inclined manner which ensures that is sprayed reaches each corner of the vial which are previously washer. After washing and drying the vials are guided to the out feed turn Table. Before reaching the out feed Turn Table a special arrangement is provided to dry the vial from the bottom side . A set of Syringes are provided on the sides of each conveyor at the exit end which sprays the air jet on the bottom part of vial resulting in the drying of the vials This machine is completely operated by PLC . A covering of Acrylic cabinet is provided in the machine which when opened up during the operation immediately stops the supply of water &air and shows the indication which alarm in the PLC. | ||