Company Information

Ask for more detail from the seller

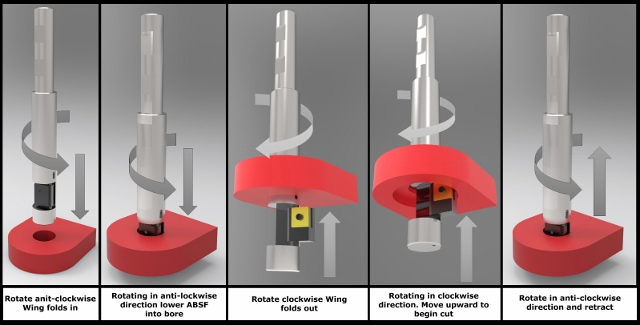

Contact SupplierMake the axis of guiding pilot shank of the automatic rear counter boring tool true to the axis of the pilot hole. Use cotter / drive-key for preventing the tool from falling down while cutting. The back spot facing tool enters the pre-drilled pilot bore in an anti-clock wise rotation of the spindle. The wing is so designed that even if it is open, it folds into the pocket on touching the job in anti-clockwise rotation. After the wing come clear of the pilot bore in anti-clock wise rotation, reverse the spindle rotation to clockwise; due to centrifugal force, the wing automatically opens up; with feed it cuts. After the spot facing is over, take the back spot facing tool little away from the job; then reverse the spindle rotation to anti-clockwise and pull the automatic back spot facing tool out of the bore. The wing automatically folds into the pocket on coming in contact with the job in anti-clockwise rotation.

Tools for this range of back spot facing are generally with HSS wings and feed rates of 0.05 & 0.03 mm per rev. in CI & MS are generally recommended. For the rest, 0.2 and 0.15 mm per rev in CI & MS, respectively are recommended, since Carbide inserts are generally used in this range. Cutting parameters depend on machine condition, clamping rigidity, hardness of job etc. For intermittent cutting, spindle speeds may almost be doubled, while feed rates are to be reduced by 30%. These are indicative parameters. Actual parameters are to be established only by trial and error.

| SPOT FACE DIA (in mm) | SPINDLESPEED (RPM) | SPOTFACE DIA (in mm) | SPINDLE SPEED (RPM) | SPOT FACE DIA (in mm) | SPINDLE SPEED (RPM) |

| 9 to 11 * | 575 | 18to 21* | 285 | 36 to 45 | 320 |

| 12 to14* | 450 | 22 to 25 | 550 | 46 to 55 | 260 |

| 15 to17* | 360 | 26 to 35 | 450 | 56 to 65 | 215 |