Company Information

Ask for more detail from the seller

Contact SupplierAutomatic Bottle Washers - RM 1 series is manufactured in 5 capacities as per chart below

RM 103, 106, 109, 112, 115

Rita RM 1 Series Automatic Bottle Washing Machines are extremely popular in wide range of industries such as

Salient features include:

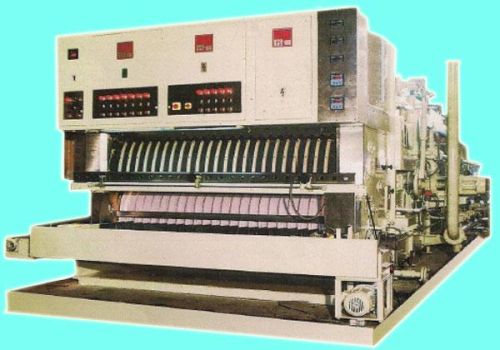

Rita RM 130/140 Automatic Bottle Washing Machines are designed for high outputs and for cleaning very dirty bottles with labels and foils. It has 3 to 4 multisoak tanks for intensive soak of the bottles and spryaing inside, outside with high pressure sprays. The movement of the main carrier chain is continuous, giving high spraying and soaking times. The infeed of bottles is with automatic auto-loader and outfeed by cam system. The machine is suitable for bottles upto 1 litre size. Steam and water consumption is kept minimum by means of energy regeneration and water recyling at every stage, resulting in a very energy and eco-friendly machine. Cleaning in place (C.I.P) is incorporated in fresh water zone for cleaning and disinfection. Automatic caustic measuring and dosing device is incorporated and optional.

Salient features:

RANGE OF INDUSTRIES:

| GERMAN TECHNOLOGY:

|