Company Information

Ask for more detail from the seller

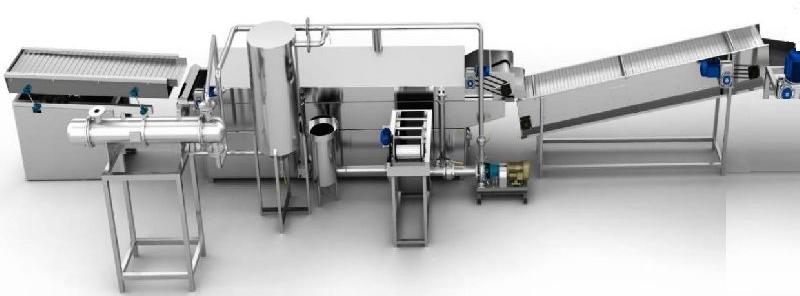

Contact SupplierOptimal Automation: An economy line with all major operation is automated except peeling and slicing.

Low production cost due to:

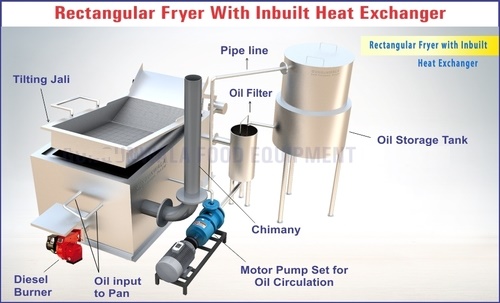

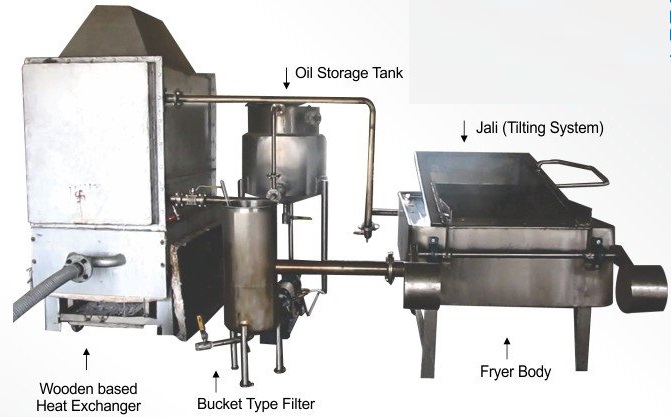

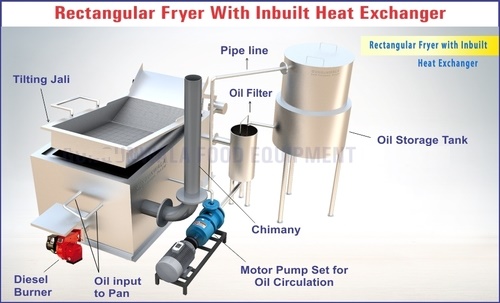

Less fuel consumption.

Less edible oil absorption - less temperature drop (delta T) gives less oil absorption.

Less manpower needed to operate the fryer.

· Better Finished product quality and longer Shelf- life.

· Optimal oil turnover ratio.

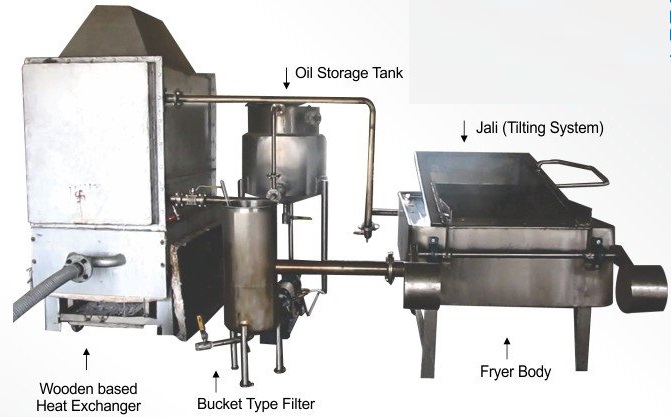

· Latest Oil Heating Technology with Heat Exchanger and low oil volume in the fryer results fresh products with long shelf life.

· Continuous Oil Filtration System removes product particles results into highest oil and product quality.

· Frying Control: Latest multi oil inlets maintain high oil flow to clear the product infeed area & provide precise control of temperature & rapid adjustment to feed change.

· High productivity.

· Better Hygiene and heat free working environment.

· Hood and Conveyor lifting arrangement gives ease of cleaning and maintenance the internal parts.

· Latest, Reliable and world class Technology.

Zero maintenance system with AISS-304 Grade SS.

Model | SAPBCL - 100 | SAPBCL - 200 |

Output: | 100 Kg/ Hr | 200 Kg/ Hr |

Fuel Options: Diesel, LPG, Natural Gas, Wood Based (HE), Thermic Fluids | ||

Edible Oil Holding Capt. | 550 Ltrs/Hr | 750 Ltrs/Hr |

Power required | 19 HP | 22 HP |

Water | 500 Ltrs/Hr | 1000 Ltrs/Hr |

Floor Space | 1200 Sq. Ft. | 1500 Sq. Ft |

Edible Oil Filtration | Continuous Filter | Continuous Filter |

Total Heat Required | 3,00,000 K Cal | 4,50,000 K Cal |

Length of the line | Apx 45-51 ft | Apx 50- 55 ft |

Lifting System | Mechanical | Mechanical |

Material of Construction | AISS-304 Grade SS | AISS-304 Grade SS |