Company Information

Ask for more detail from the seller

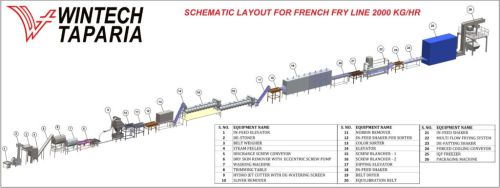

Contact SupplierProcess equipments for continuous production of par rried french fries. Capacity 1000Kg/hr. It is based on fresh Graded potatoes, having 21% solid content and ideal processing conditions. All the equipments are manufactured on a Swedish technical know how and fabricated in stainless steel-304 only. Coated Fries- we offer coated fries option with a continuous coating in line with the frying line. We offer a Coated French Fries- A new product for your market! Washing & Peeling Infeed Elevator Unit for receiving potatoes and feeding at controlled rate to the Destoner. Destoner The machine is used to remove the Dirt & Stones on the farm picked potatoes and to elevate the same to the peeler. The turbulence of water removes the adhered sand particles and also the stones. The screw feeder, driven by a constant speed motor carries the potatoes into the peeler. The unit incorporates trap doors, which can be used for cleaning after the production. Certain amount of washing is achieved to assist better peeling. Abrasive Peelers – 2 Nos. For continuous peeling of potatoes with minimum peel losses. Specially designed for safe running and low maintenance cost. Easy access for inspection & cleaning. Easy replacement of rolls. Abrasive rollers coated with special abrasive powder. Trimming Cum Inspection Table Finally peeled potatoes to be inspected on Inspection conveyor. The equipments also provide for Trim station mounted on either side of table to facilitate trimming and disposal through waste chute. Cutting, Blanching, Cooling & Drying Inclined Elevator To feed Peeled Potatoes to the Cutter for French Fry Line. French Fry Cutter Sourced From Europe For cutting of potatoes into sticks. Stick Dimensions: 3 mm to 16 mm Material: stainless steel, glass blasted. Drive components & other parts made of normal material.