Company Information

Ask for more detail from the seller

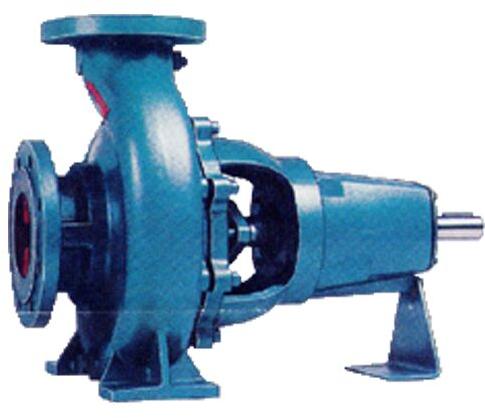

Contact Suppliermore than 3mm corrosion allowance (cast iron) for extended use on corrosive applications. Back pull out construction allows rotating assembly to be withdrawn without disturbing the suction and delivery connections. One piece self vented foot mounted , center suction volute casing , single stage , closed / semi open dynamically balanced impeller.

• flange drilling standards as per din 24255 / iso 2858 or as per customer’s requirement.

• designed for 16 bar working pressure with optional casing for a working pressure of up to 20 bar.

• special monoblock versions available on request.

• heavy –duty, deep- grooved bearings with minimum 50,000 hours operating life under normal condition. (grease lubricated , oil lubrication available on request)

• a robust and solid construction that guarantees long life even under high suction pressure conditions.

• heavy –duty , stiff solid shaft design with low l3/d4 ratio ensures less than 0.05 mm shaft deflection at the seal face in all operating condition. This extends the seal life.

• seal housing is constructed to accommodate different seal / gland designs, so as to meet the severe heavy-duty requirements. (standard is gland packing , seal version on special request)

• excellent parts interchangeability reduces inventory levels for spare parts to a minimum.

• special design for high temperature thermic fluid available on request.

• motor or engine driven sets.

cast iron construction with en-8 shaft , ss-410 sleeve, gland packing and special material like wcb , cf-8 , cf-8m, alloy 20 , ss-304 , ss-316 fabricated etc on request

for pumping clear / turbid water / chemicals & volatile liquids.

air conditional plants, power station, mine drainage, sprinkle systems fire fighting, booster service, oils brine.

delivery size up to 250 mm,

capacity up to 990 m3/hr,

head up to 120 meters

rpm 500 to 3600