Listing ID #3931476

Company Information

Ask for more detail from the seller

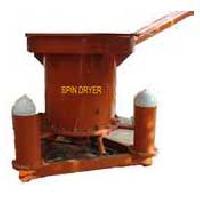

Contact SupplierThe hot flue gas from the boiler are made to pass through the dryer under forced draft. The wet mill bagasse is fed through a rotary air lock feeder at the bottom of the dryer. It is then carried upward in a co-current mode with the hot flue gas at a calculated velocity based on Average Particle Retention Time (APRT). During this process, bagasse moisture evaporates and the dried bagasse is subsequently separated through a high efficiency cyclone separator.

The dried bagasse is continuously evacuated from the bottom of the cyclone(s) through air-lock valves for onward feeding to the boiler. Adequate automation including differential pressure monitoring is provided.

Advantages

1.Moisture reduction up to 37% & below.

2.It increases boiler efficiency by minimum 5%.

3.Differential pressure control across drier to avoid bagasse chock up.

4.Stainless steel constructed parts at critical locations.

5.It reduces excess air requirement, which in turn reduces power consumption of boiler fans.

6.It optimizes bagasse burning and improves clean emission.

7.It saves bagasse due to improvement in boiler efficiency or alternatively more power can be exported to grid.

8.Dry bagasse ensures a faster response to load and maintains boiler pressure/temperature stable.

9.It generates high temperature inside boiler furnace and improves efficiency.

10.Due to complete combustion of fuel, wear and tear of boiler parts reduces, thereby reducing maintenance cost.

11.VFD Controlled booster fan to cater moisture & particle size variation.

12.Improvement in the combustion performance resulting in better load response characteristics.

13.Typical surplus bagasse obtained from 90 TPH boiler will be 65 TPD approx.