Company Information

Ask for more detail from the seller

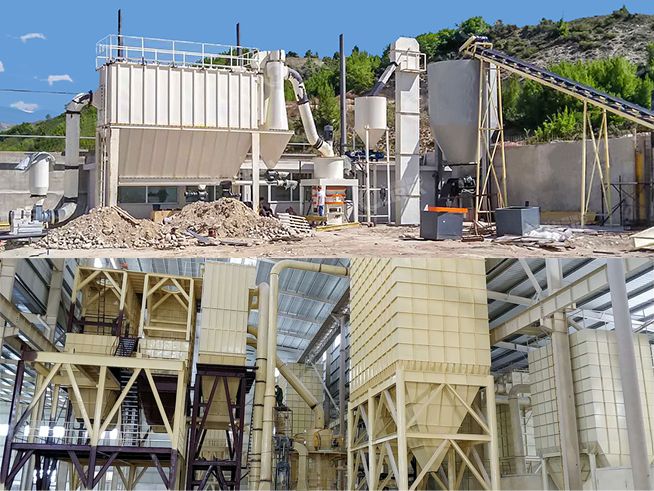

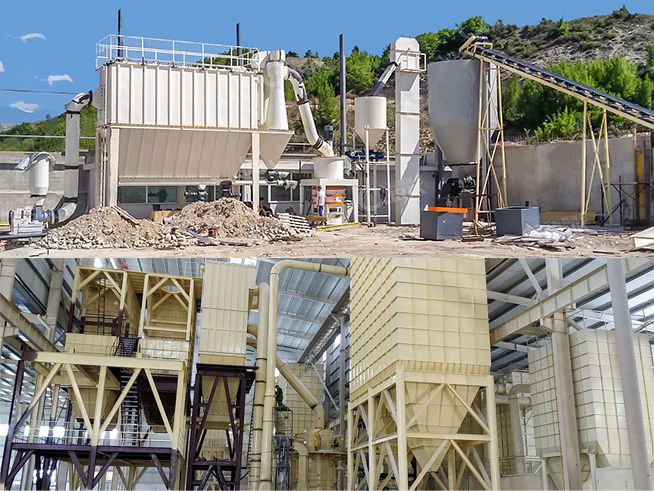

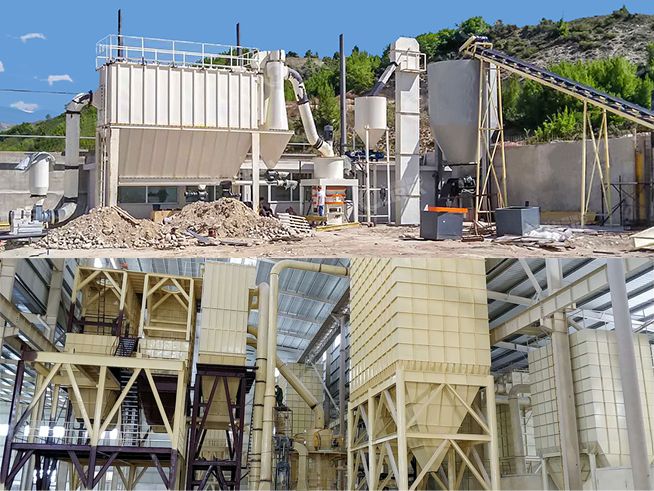

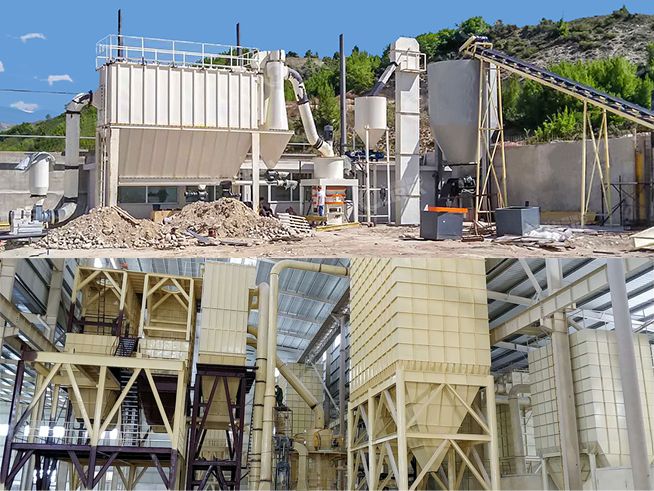

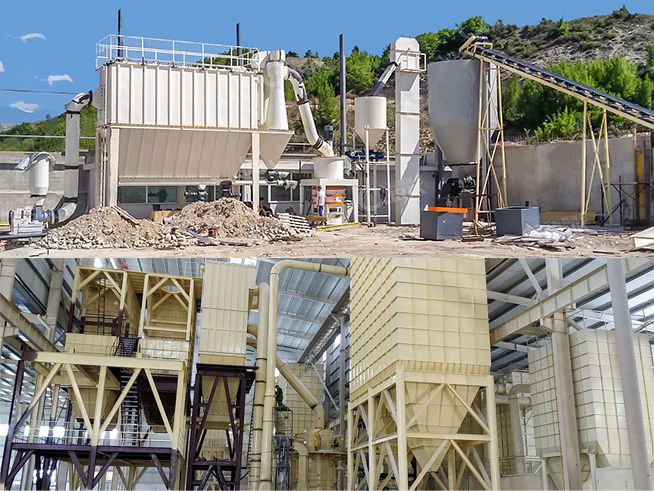

Contact SupplierLYHM crushes materials by impact, extrusion and pulverizing. When the turntable revolves round the main shaft, the grinding rollers will be stretched out to the grinding ring by centrifugal force, and press the grinding ring inner layer and rotate round the axis pin. Through the clearance between the grinding rollers and the grinding ring, the material will be crushed by the impact, extrusion and grinding of the grinding rollers. The material is ground between the first layer of the grinding rollers and grinding ring, then falls into the second layer and is ground again as per the same principle. After the material is ground by the grinding roller in the last layer, it will fall onto the turntable under gravity and brought to the interlayer between the inner and outer layers of the cylinder by negative pressure airstream, and once again rise to the air classification system for separation. Qualified powder will pass through the classifier and enter into the pulse dust collector; coarse materials will be directly knocked down to the grinding table and resettle in the pulverizing room for pulverization. The turntable is distributed in multiple layers. Thus, the material is sufficiently pulverized to reach the desired fineness.