Company Information

Ask for more detail from the seller

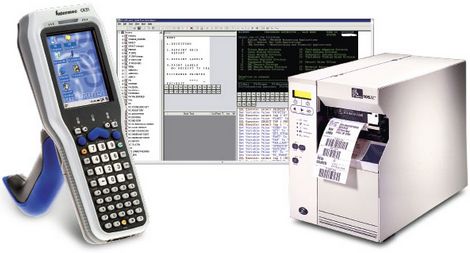

Contact SupplierDefect Part Traceability System Thru Barcode Technology

Find the Traceability of Your Rejected Part Through Barcode Technology

Now, you can easily track the traceability of your rejected part through Barcode solution including controlling and storing of critical process parameters like temperature, Pressure, Rpm, Torque, Displacement etc. in your software database.

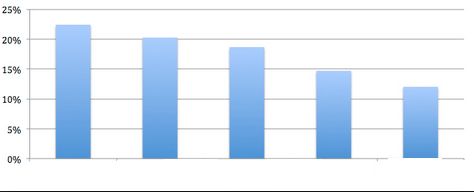

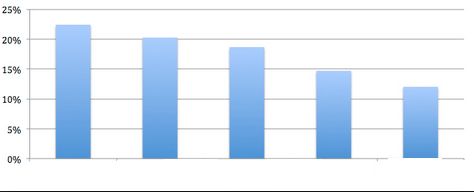

Advantages of the traceability tracking system :

| Check Point | Action Plan |

|---|---|

| Bar coding of Rivets for traceability | To be implemented by rivet supplier - Discussion 30.Mar. |

| Supply qty to be standardized | To be discussed - 30.Mar |

| Input data to system by Riveting machine operator | Once P/No: is called, automatically program to call the sub part:, qty per packet etc and to error proof the machine once lot qty complete |

| Part sticker Bar coding | Code details to be shared with service provider and feasibility sought Design change request for increase in sticker size to be raised |

| Box sticker bar coding | Station fully manual-small scale automation to be made to provide information to print the right sticker |

| Station fully manual-small scale automation to be made to provide information to print the right sticker | Pop up screen to select the available boxes and to error proof the same by integrating with G2B and by not permitting dispatch sticker without this process |

| Poke yoke data base | Poke yoke for rivet presence-Data to be stored along with the above traceability database |