Company Information

Ask for more detail from the seller

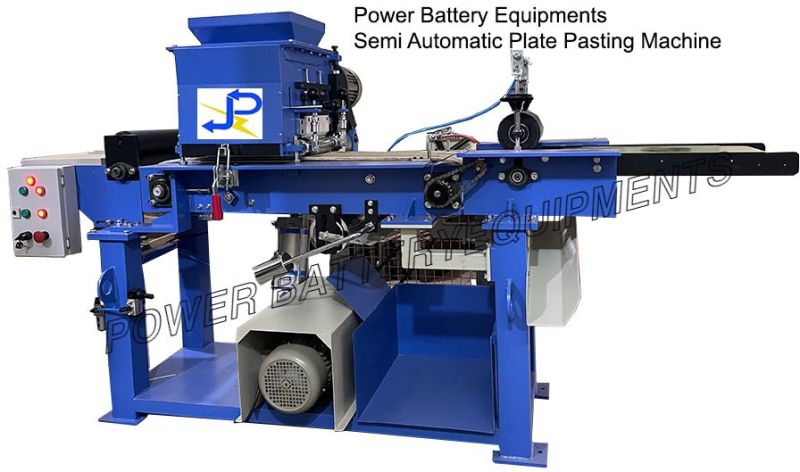

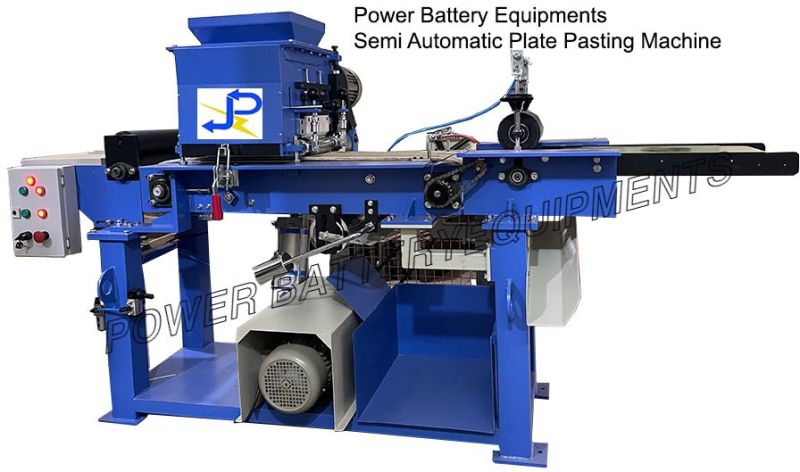

Contact SupplierA plate pasting machine is an industrial machine used in the production of lead-acid batteries, particularly in the manufacture of the positive plates of the battery. The process involves applying a paste (typically made of lead oxide, sulfuric acid, and other components) onto the lead plates or grids, which are then used to form the electrodes of the battery.

Key Features of a Plate Pasting Machine:Pasting Process: The machine automates the process of applying a uniform layer of paste onto the lead grids. This is a crucial step because the quality of the paste layer affects the battery's overall performance.

Types of Machines: There are different variations of plate pasting machines depending on the capacity and type of battery being produced:

Speed and Efficiency: Modern plate pasting machines are designed to be highly efficient, capable of processing a large number of plates in a short period of time, ensuring consistent quality across the entire batch.

Automation: These machines typically operate in an automated environment, where plates are fed into the machine, pasted, and then sent to the next stage in the battery production process, such as curing, drying, and assembly.

Paste Preparation: The paste itself is prepared using a precise mix of materials and is kept in a controlled environment to maintain its consistency. The machine ensures that the paste is applied evenly, without any lumps or air pockets.

Applications: Plate pasting machines are used in the manufacture of various types of lead-acid batteries, including those used in automotive, industrial, and stationary applications.

These machines play a critical role in ensuring the efficiency, longevity, and reliability of the batteries produced.