Company Information

Ask for more detail from the seller

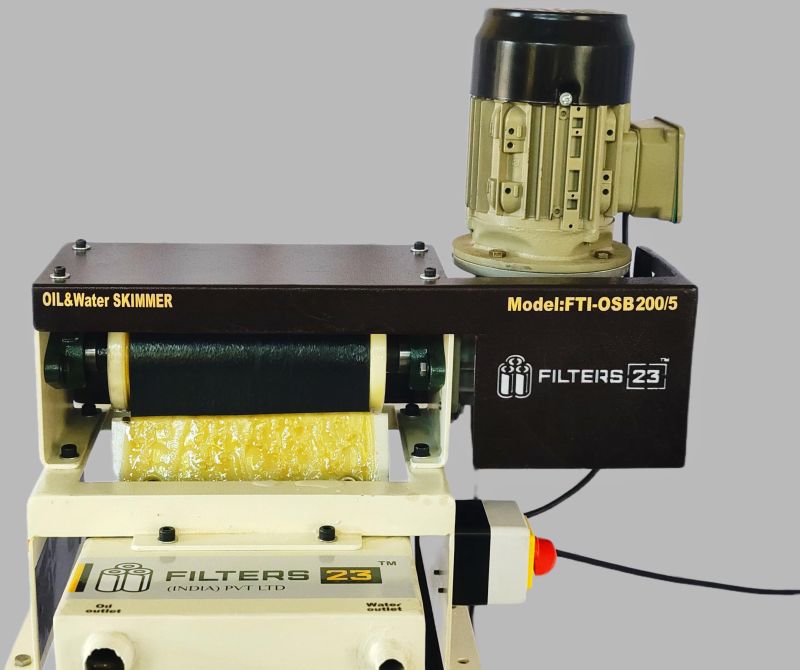

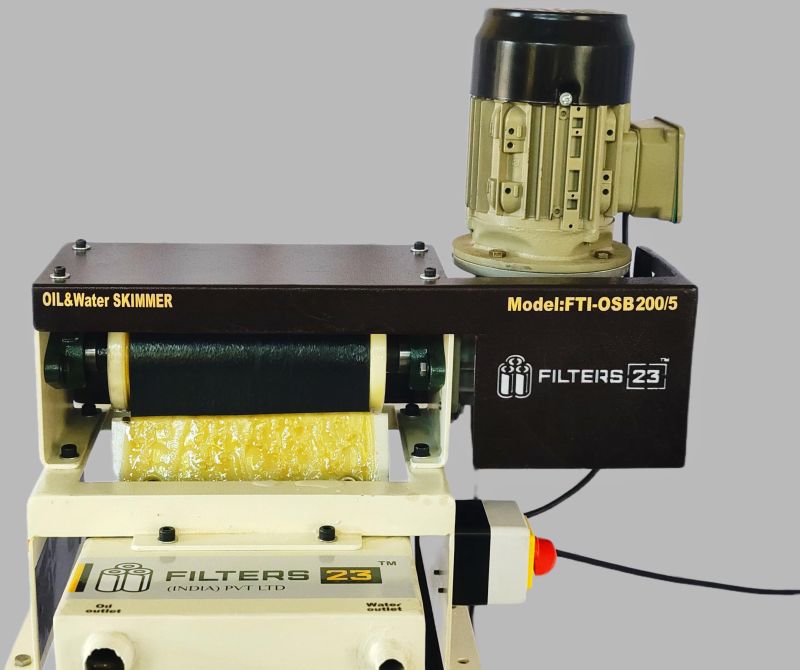

Contact SupplierBelt Type Oil Skimmer

FILTERS23 INDIA`S Belt type oil skimmer is a mechanical device used for removing oil, grease, and other hydrophobic (water-repellent) liquids from the surface of water or other liquids. These skimmers are often employed in industrial and environmental applications to effectively separate and collect oil and grease contaminants from water bodies, process tanks, or other liquid surfaces. Here's how a belt type oil skimmer typically works and some key features:

Working Principle:

Endless Belt: A belt type oil skimmer consists of an endless loop of belt or a similar material. The belt is typically made of materials that repel water but attract oil, such as oleophilic (oil-attracting) materials.

Deployment: The skimmer deploys the belt into the liquid to be skimmed. The belt floats on the surface of the liquid, and a portion of it is submerged.

Surface Contact: As the belt travels along the liquid's surface, it comes into contact with the oil or grease on the surface. Due to its oil-attracting properties, the belt adheres to the oil, and the oil sticks to the belt's surface.

Oil Removal: The belt continues to move, carrying the adhered oil away from the liquid's surface. As it moves, the belt passes through a scraper or wiper mechanism that removes the oil from the belt's surface.

Collection: The collected oil is typically directed into a separate collection container or storage tank. The collected oil can then be periodically removed for disposal or recycling.

Key Features:

Adjustable Speed: Many belt type oil skimmers feature adjustable speed controls, allowing operators to regulate the skimming rate based on the application's specific requirements and the volume of oil to be removed.

Self-Adjusting: These skimmers are designed to automatically adjust to changes in the liquid level, ensuring efficient oil removal even if the liquid level fluctuates.

Efficiency: Belt type oil skimmers are known for their high efficiency in removing oil and grease from water or other liquids. They can effectively remove both thin sheens of oil and thicker layers of oil.

Low Maintenance: They typically require minimal maintenance, with routine cleaning and occasional replacement of wear parts being the primary maintenance tasks.

Versatility: Belt type oil skimmers can be used in a wide range of environments, including industrial wastewater treatment, oil spill response, coolant recycling, and other applications where oil-water separation is necessary.

Compact Design: Their compact and portable design makes them suitable for various settings and locations.

Environmental Benefits: By removing oil and grease from water bodies, belt type oil skimmers help protect the environment by preventing the contamination of natural water sources.

Belt type oil skimmers are valuable tools for industries dealing with oily wastewater or encountering oil contamination problems. Their efficient and reliable operation contributes to cleaner and more environmentally friendly water management by effectively separating and collecting oil and grease contaminants.