Company Information

Ask for more detail from the seller

Contact SupplierWith Technology Upgradation, automatic bending machine is now being used in high production plant of 8mm-32mm TMT bars resulting in following benefits –

1. Drastic Reduction in labor.

The process of bending starts after Shearing of TMT Bars from Cold Shearing Machine installed after Cooling Bed.

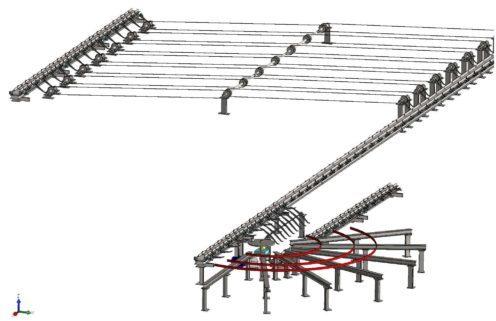

After shearing of Standard 12 meter long Bundle of TMT Bars, it will get transfer to another 12 Meter Conveyor through Skid type transfer cooling Bed. The whole set of Bundles of 40-50 TMT Bars get transfer together through this cooling bed to the conveyor. The skid transfer type cooling bed consists of Chain, Dog, Sprocket and structure.

Skid Transfer Type Cooling Bed is 8+8 m = 16 Meter wide and 12 Meter long. This is a slow speed transfer system, which keeps on moving at a very slow speed and paralley labor bundles 10 kg TMT Bars which automatically gets transfer to the Delivery Roller Table through kick off system. In this Skid Transfer type Cooling Bed, the short length of TMT Bars, (which is left at the end after cutting of all 12 Meter TMT Bars), are transferred at the end time. This short length material, after reaching to the conveyor from skid transfer, is thrown out at the open space.