Company Information

Ask for more detail from the seller

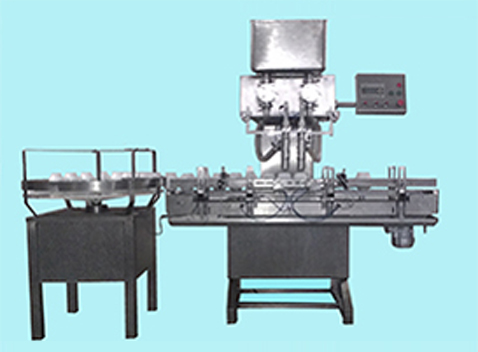

Contact Supplierbasic machine suitable to fill 50ml to 1 litre jars

above the machine-working surface, which height is 800 to 850mm, the following units are placed.

s.s.304 steel structure.

it depends on the fill size and viscosity of the products.