Company Information

Ask for more detail from the seller

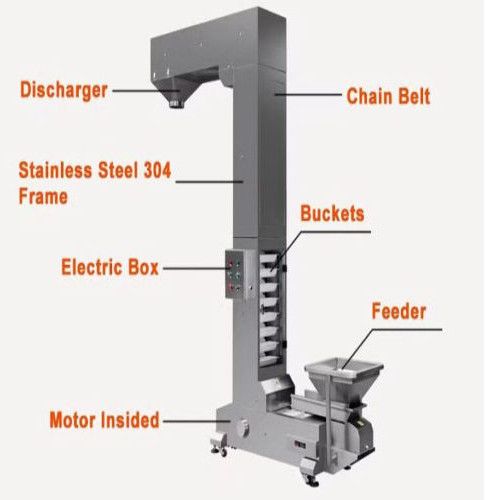

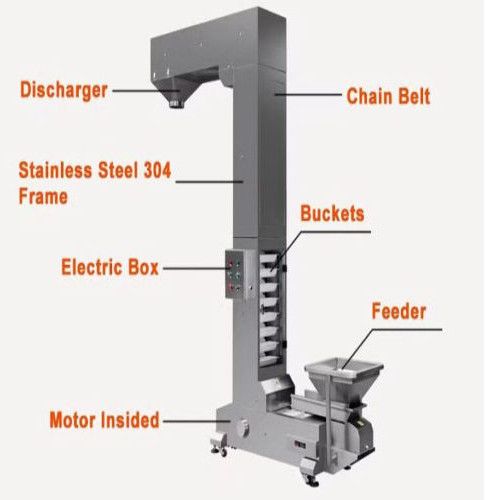

Contact SupplierA Bucket Elevator Conveyor is a vertical conveying system used to lift bulk materials safely and efficiently from a lower level to a higher level. It is widely used in industries where powders, granules, or small solid materials need to be transferred in a continuous and dust-free manner.

A bucket elevator conveyor is a system that uses buckets attached to a continuous belt or chain to vertically transport bulk materials like grain, powder, or granules. The buckets scoop material from a lower point, lift it to a higher point, and then discharge the material, either through centrifugal force or continuous discharge. These systems are essential for industries such as agriculture, mining, and manufacturing for efficient, continuous vertical material handling.

The rotary bucket conveyor (referred to as the rotary bucket) is a conveyor that uses two special material chains as traction components, and the two sides of the hopper are fixed on the chains and continuously arranged. It is loaded by inflow and automatically flipped and unloaded at low speed.

Product Features :-

Applications

Food & Agro: Rice, wheat, maize, sugar, pulses.

Cement & Minerals: Clinker, limestone, fly ash, gypsum.

Chemicals & Fertilizers: Crystals, powders, granules.

Pharma & Hygienic Use: Fine powders, specialty chemicals.

Other Bulk Materials: Biomass pellets, sand, coal.

Optional configuration :-

Construction of the hoist : Hoists are generally composed of basic components such as motors, reducers, conveyor sprockets, chains, hoppers, etc.

1. Motor: As the power source of the hoist, it is used to provide mechanical energy.

2. Reducer: Converts the high-speed rotation output by the motor into the low-speed rotation required for the conveyor sprocket.

3. Conveyor chain wheel: It is an important component of the elevator, receiving power from the machine and acting on the hopper through chain transmission, carrying animal material upward along the vertical direction of the elevator.

4. Chain: Transfer the power of the conveying sprocket to the hopper.

5. Hopper: used to store and transport materials, transporting them up the elevator.