Company Information

Ask for more detail from the seller

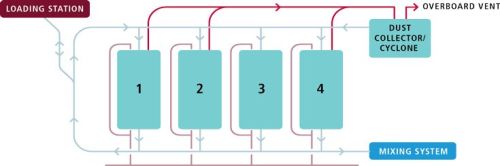

Contact SupplierCameron bulk storage and transfer systems are a complete solution for bulk barite, bentonite, and cement storage. Each system is custom-engineered to meet your production requirements and offers efficiency-enhancing options such as full instrumentation packages, remote valves, product automation, and remote system control capabilities.

Specifications

Bulk MudCement Storage and Surge Tanks

Tank design minimizes potential wastage, clogging, and maintenance downtime

Three-legged or skirt-support design provides superior stability

Aeration panels in cone and base ensure optimal flow during pressurization and discharge processes and minimize the amount of material left in the tank after emptying

Full instrumentation package

Remote, real-time monitoring and control capabilities for repetitive tasks

Meets ASME standards

ABSDNV certification

Dust Cyclone and Collector Unit

Reclaims and recycles costly powder dust into the bulk storage system

Automatic filling, separation, and discharge

Proven effective operation in any climate condition

Single cyclone-type separator delivers ongoing high operational efficiency

Cement Discharge Valve

Optimizes the fluidization process within the silo tank

Provides high levels of precision, easier control, and better results during bulk cement transfer

Low maintenance

Electrically actuated control valve

Cell Feeder

Enables automatic dosing of bulk material from surge tank into mixing hoppers

Improves dosing accuracy

VFD-controlled