Company Information

Ask for more detail from the seller

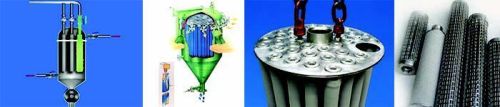

Contact SupplierOne of the most common and efficient of all pressure filters is the Candle Filter. These operate on a batch or a semi-continuous mode. The loads in the liquid streams can be in the 2-10% range solids. Very efficient to filter fine solids and use both surface and cake filtration. Diva Envitec Pvt Ltd makes Candle filters in cloth, SS membrane, SS Mesh, Wedge screens, SS Laminate material of constructions.

Applications

Feature and Advantages

Process Operation

Candle Filters give dry cakes by separating solids from liquids, additionally these can also be used for thickening to produce a concentrated slurry by removal of the liquid phase as filtrate. Semi-continuous mode is possible when Candle Filters operate on very short cycle times taking advantage of the high filtration rates whilst the cakes are still thin.

The flow of liquids can be from either inside-to- out or outside-to-in depending on the type of configuration chosen.

Technical Specification