Listing ID #3877878

Company Information

Ask for more detail from the seller

Contact SupplierFeatures:

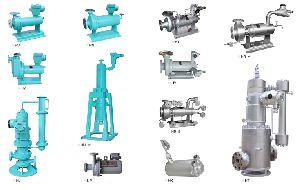

The high reliability of these pumps makes them suitable for pumping of toxic, hazardous liquids, high temperature, high pressure services in nuclear power plant, Lithium Bromide circulation in refrigeration plant, Ammonia transfer in fertilizer plants, refineries, chemical and pharmaceutical industries and other process industries for handling toxic, hazardous or expensive fluids.

Construction FeaturesKBL Canned Motor Pumps are developed, based on the technical know-how from Nikkiso Co.Ltd., Japan. Canned Motor Pump is a centrifugal pump with pump and hermetically sealed electric motor mounted on single shaft thus eliminating the requirement of mechanical seal or other sealing device. Entire rotating assembly is immersed in the liquid, and motor stator and rotor are isolated from the pumped liquid with corrosion resistant, non-magnetic liner and sleeve. A part of the pumped liquid is by-passed through the motor, for cooling of motor and lubricating the bearing.

CasingAxial suction and top centre line delivery. Smooth hydraulic passages for high efficiency. Volute type casing connected to liner disc and adapter plate.

ImpellerEnclosed/semi-open type, statically and dynamically balanced. Hydraulic balancing of impeller achieved by means of automatic thrust balance arrangement.

Auxiliary impeller for bearing lubrication and motor cooling is also available.

ShaftStainless steel shaft accurately machined and ground. It is supported by ceramic/carbon graphite sleeve bearings in motor which are lubricated by pumped liquid. A return passage for circulating liquid for cooling motor and bearing lubrication available through the shaft.

Direction of RotationClockwise viewed from driving end.

Electric Motor2/4 pole, 3 phase, 415V, 50 Hz, Class of insulation F, H or C. Flame-proof and explosion proof construction with built-in safety devices available.

FlangesStandard: Drilled to ANSI-B 16.5 Class 300.

Optional: Drilled to DIN/IS/ASA/BS.

Casing: Stainless Steel, CF8M, CF3M

Impeller/Auxiliary Impeller: Stainless Steel, CF8M, CF3M

Stator Liner: Hastelloy, Inconel, SS316L

Rotor Sleeve: Hastelloy, Inconel, SS316L

Bearing: Ceramic, Carbon graphite

Thrust washer: Tungsten Carbide, SS316L with HCR/Ceramic coating

Shaft Sleeve: Tungsten Carbide, SS316L with HCR/Ceramic coating.