Company Information

Ask for more detail from the seller

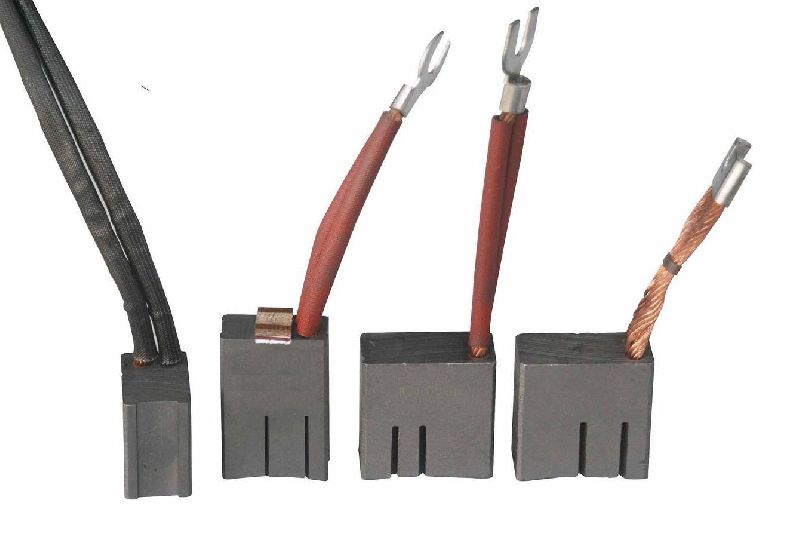

Contact SupplierA carbon brush is a device for maintaining electrical contact from a static to a rotating part in a motor or generator, a moving surface such as a commutator or a slipring, ensures a spark-free commutation and performs the following critical functions-

• Deliver or collect electric current from rotating part of a machine.

• Perform the duty of commutation i.e. changing the direction of the flow of current.

• Keep the commutator or slipring surface clean & smooth with a protective film of copper & carbon graphite to maintain good contact without excessive wear.

Carbon brushes have been used for a long period of time and are preferred due to their excellent properties like good electrical & thermal conductivity and high temperature resistance which make it a highly suitable material for current transmission in rotating electrical machines. They are widely used in the automotive industry, iron & steel industry, cement plants, paper mills, domestic appliances, generators & motors of the railways. A carbon brush can be made of one or more carbon blocks and equipped with one or more shunts / terminals.

At Malabar Carbons, all our carbon brushes are manufactured as per IS: 3003 PART 1-3(78) on imported cutter/grinder precision machines. Tamping operations are done on automatic imported tamping machine. The brushes are then tested as per IS 3003 such as Millivolt drop, Pull strength, Endurance test etc. Then the sockets are sealed by a special sealing compound to strengthen the tamping. High powered magnifiers are used to detect any hairline cracks before packing.

Our copper carbons have a high ratio of copper of almost 70% while other manufacturers have a ratio of only about 50 to 60 %. Our brushes will give a longer life and better commutation thereby producing greater electrical energy ensuring better performance.