Company Information

Ask for more detail from the seller

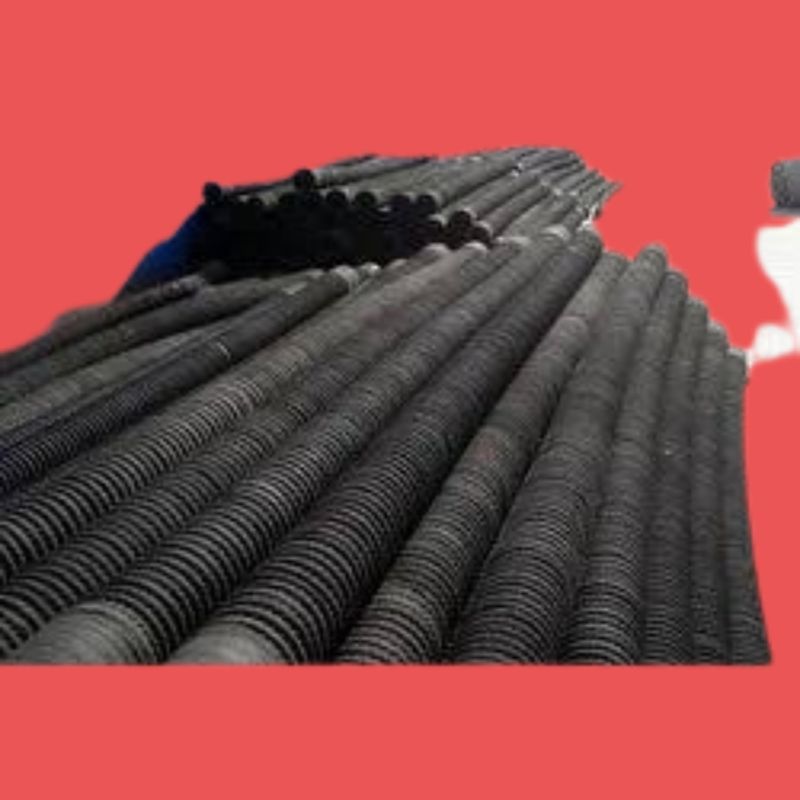

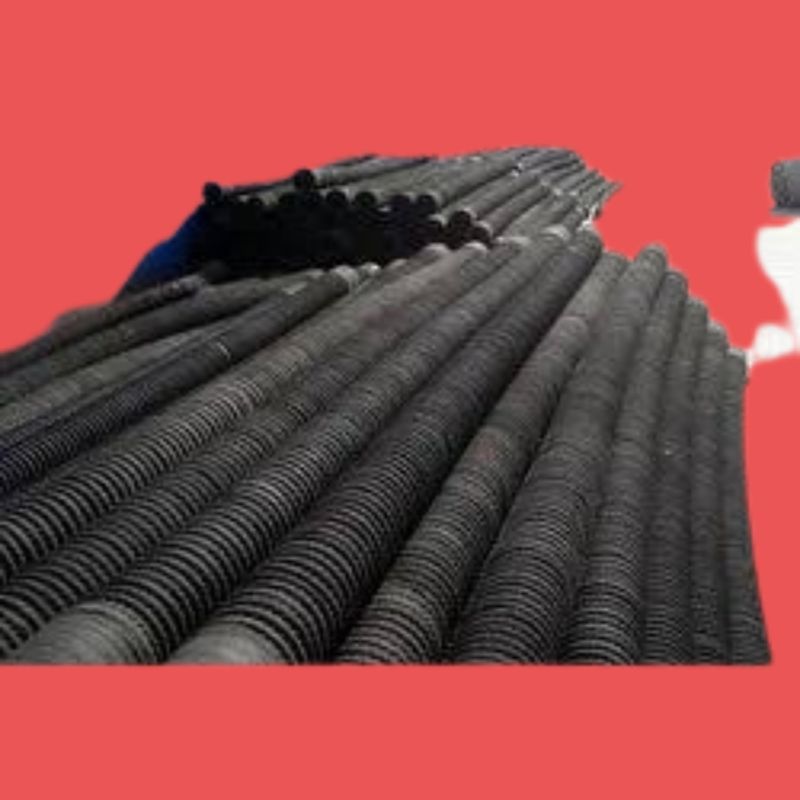

Contact SupplierSandhya Enterprises Manufacturer and Supplier of Cement Grounding Rubber Hose.Rubber Hose for Cement Grouting MEETS IS : 5137 W.P. 10kgfcm2 MIN. B.P. 40 kgfcm2 25.0 31.0 38.0 50.0 63.0 75.0 100.0 125.0 150.0 200.0mm 250.0mm Tube : Highly abrasion resistant soft natural rubber compound. Reinforcement : WovenBraided or spirally wound textile of high strength synthetic fibres. Electrical bonding : low resistant electrical bonding wire in-corporated between the reinforcement plies to pro vide electrical continuity along the whole length of the hose. Cover : Cloth marked finish cover, resistant to weather and abrasion.I believe you are referring to an air conveying rubber hose, which is a specialized hose designed for the transportation of air or gases in various industrial applications. It is commonly used in pneumatic systems, air compressors, and air conveying systems where a flexible and durable hose is required to transport compressed air or gases.

The key features and characteristics of an air conveying rubber hose include:

1. Material: Air conveying rubber hoses are typically made of high-quality rubber or synthetic elastomers that are resistant to abrasion, weathering, and aging. The material should also have good flexibility to allow for easy installation and maneuverability.

2. Reinforcement: The hose is reinforced with high-strength textile or synthetic fibers, such as polyester or aramid, to provide structural integrity and prevent the hose from bursting under pressure. The reinforcement also helps to maintain the hose's shape and flexibility.

3. Pressure resistance: Air conveying rubber hoses are designed to withstand the specific working pressures involved in air or gas transportation. They should be able to handle the pressure generated by air compressors or pneumatic systems without leakage or failure.

4. Size and fittings: Air conveying rubber hoses are available in various diameters and lengths to suit different application requirements. They can be fitted with standard couplings or connections, such as threaded fittings or quick-connect couplers, for easy attachment to equipment or piping systems.

5. Temperature range: The hose should be able to withstand the temperature extremes typically encountered in air conveying applications. It should remain flexible and functional even in high or low-temperature environments.

6. Anti-static properties: In certain applications where static electricity buildup can be a concern, air conveying rubber hoses may be designed with anti-static properties. This helps to prevent the buildup of static charges that could pose a safety hazard or damage sensitive equipment.

Regular inspection and maintenance of the air conveying rubber hose are necessary to ensure its proper functioning. This includes checking for signs of wear, damage, or blockages that could restrict airflow or compromise the integrity of the hose.

It is important to consult with reputable suppliers or manufacturers of air conveying rubber hoses to ensure the selection of the appropriate hose that meets the specific requirements of the air conveying system and complies with industry standards and regulations.