Company Information

Ask for more detail from the seller

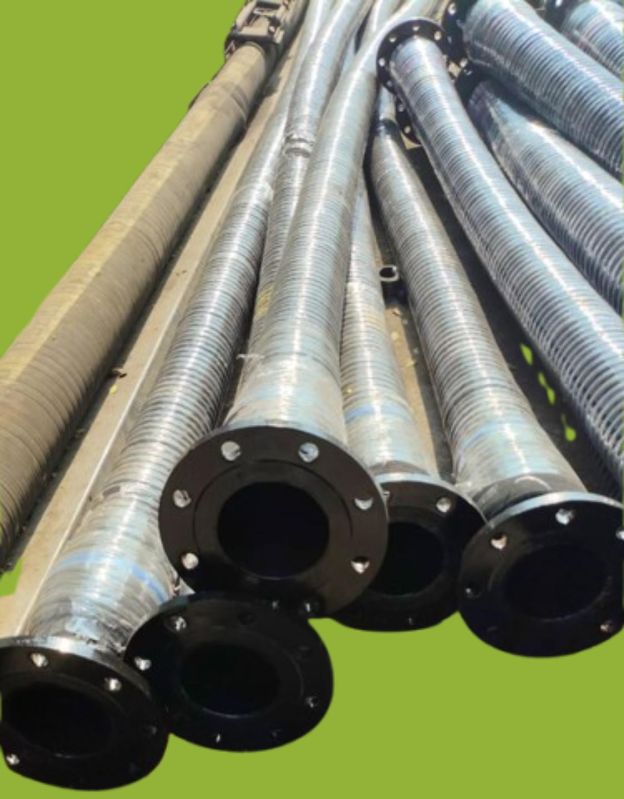

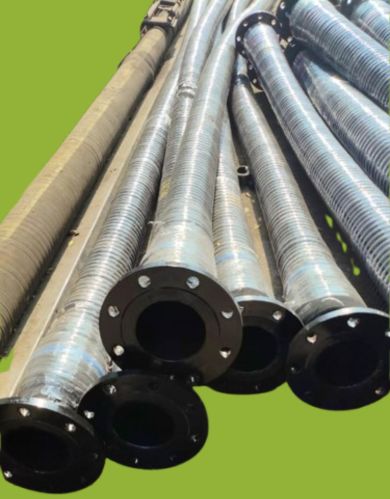

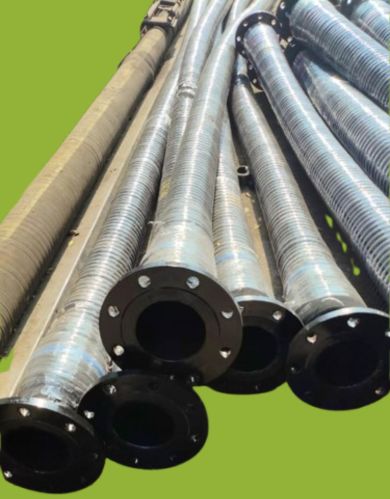

Contact Suppliersandhya enterprises manufacturer and supplier of cement grounding rubber hose.rubber hose for cement grouting meets is : 5137 w.p. 10kgfcm2 min. B.p. 40 kgfcm2 25.0 31.0 38.0 50.0 63.0 75.0 100.0 125.0 150.0 200.0mm 250.0mm tube : highly abrasion resistant soft natural rubber compound. Reinforcement : wovenbraided or spirally wound textile of high strength synthetic fibres. Electrical bonding : low resistant electrical bonding wire in-corporated between the reinforcement plies to pro vide electrical continuity along the whole length of the hose. Cover : cloth marked finish cover, resistant to weather and abrasion. enterprises an iso:9001;2015 certified company is manufacture and supplier of cement feeding rubber hose as per is:5137:990 specification: size: 3” id to 16” id end fitting: ms flange as per asa 150 # ansi 16.5 drilled and din specification. working pressure -10 to 15kg/cm2 color: black vaccum:500 to 700hg temperature- 150deg c top: plain and corrugated. lining : synthetic rubber high ablation resistance. reinforcement: high quality and heat resistance fabric and tyre cord reinforcement. helical wire: 16 wwg to 8 swg high tensile spring helical wire cover: weather resistance synthetic rubber regular size: sandhyaflex-cfrh-80nb-3inch id sandhyaflex-cfrh-100nb-4inch id sandhyaflex-cfrh-125nb-5inch id sandhyaflex-cfrh-150nb-6inch id sandhyaflex-cfrh-200nb-8inch id sandhyaflex-cfrh-250nb-10inch id sandhyaflex-cfrh-300nb-12inch id sandhyaflex-cfrh-140nb-14inch id sandhyaflex-cfrh-400nb-16inch id A cement feeding rubber hose, also known as a cement discharge hose or cement delivery hose, is a specialized hose used for the transfer of cement or concrete in construction and industrial applications. It is designed to withstand the abrasive nature of cement and concrete mixtures while providing a flexible and reliable conduit for their transportation. Cement feeding rubber hoses are typically constructed with a durable inner lining made of synthetic rubber or natural rubber compounds. This lining is designed to resist the abrasion and degradation caused by the movement of cement and concrete materials. It is reinforced with multiple layers of high-strength synthetic fibers or steel wire braids to provide structural integrity and resistance to bursting under pressure. The outer cover of the hose is often made of a synthetic rubber compound that provides protection against external factors such as weathering, UV radiation, and physical damage. It may also have a fabric impression or wrapping for added reinforcement and protection. Key features and characteristics of cement feeding rubber hoses include: 1. Abrasion resistance: The inner lining of the hose is specifically formulated to withstand the abrasive action of cement and concrete mixtures, reducing wear and extending the hose\\\'s service life. 2. Flexibility: Cement feeding hoses are designed to be flexible and maneuverable, allowing for easy handling and movement during the cement delivery process. 3. Pressure resistance: The hose is constructed to withstand the working pressures involved in cement and concrete pumping, ensuring safe and reliable operation. 4. Compatibility: Cement feeding hoses are engineered to be compatible with cement and concrete mixtures, ensuring that the hose material does not react or degrade when in contact with these materials. 5. Size and fittings: Cement feeding hoses are available in various diameters and lengths to suit different applications. They can be fitted with standard couplings or connections for easy attachment to pumping equipment or other components of the cement delivery system. It is essential to follow the manufacturer\\\'s guidelines and recommendations for the proper selection, installation, use, and maintenance of cement feeding rubber hoses. Regular inspections and preventive maintenance are necessary to identify signs of wear or damage and to ensure the hose\\\'s integrity and performance. Con