Company Information

Ask for more detail from the seller

Contact SupplierWe offer cement plant. Vrrk:- latest technology in mini cement plant :- capacity ( 30 tpd to 600 tpd ) raw materials :

1.limestone (purity not less than 88% total carbonate)

2.clay ( black soil ) should be buttery

3.coke breeze petro coke

4.laterite ( used if clay do not have 16% fe2o3)

5.gypsum (additive used during clinker grinding) :

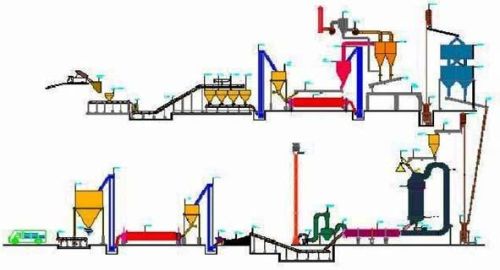

1. Raw mill section :

all the raw materials should be of less than 25 mm size. If the size of the raw material is bigger than 25 mm, it has to be crushed through a crusher and hammer mill. All the materials are crushed stored in the storage yards through belt conveyors.

Now, the raw materials are taken as per their required percentage with the help of a weigh belts( control by plc ).the measured materials is went to feed belt conveyor and after that shifted to a feed hopper through elevator .the feed of material is controlled with the help if ratchet feedertable feeder.

2. Kiln section :

from surge silo the mixed raw materials are taken to nodulizer with the help of a screw conveyor.then water is sprayed on the mix (10%) to make nodules with the help of nodulizer. These nodules are fed into the kiln through feed chute for burning and fusion. The temperature goes up to 1350oc in the burning zone. The material travels very slowly in the kiln. All the material get fused here. After passing through the burning zone the material starts cooling slowly. The clinkerisation starts and the clinker finally comes out of the kiln.

3. Clinker grinding section :

the clinker so obtained is crushed to make its size less than 25 mm. The crushersroller crusher are used to crush the clinker. The gypsum is used as an additive. Both material crushed together and went into feed hoppers through elevator. They are collected through the feeders provided below the feed hoppers. The clinker and gypsum are mixed in certain ratios (5%). So, the weigh belt is used to weigh the ingredients for mixing. A modern electronic weighing & control system .