Company Information

Ask for more detail from the seller

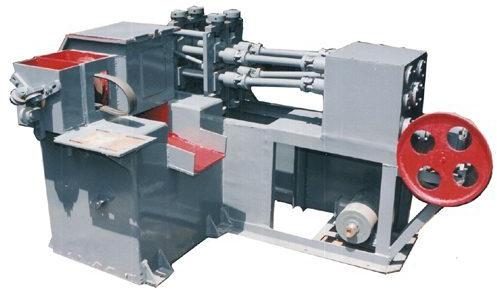

Contact SupplierWorking Principle :

The bar to be turned is supported between an entry guide and steedy rollers.The cutting tools is mounted in a cutter head which in turn is fixed on a revolving spindle and the bar to be trun is move by feed rollers against the revolving cutter head on the bar.

Capacities :

Capacity of turning black bar (dia) : 16mm-50mm

25mm-75mm

Type of cutter head: Duplex type with pressure roller & carbide button tool.

Depth of cut on surface: 2 mm

Turning Head Stock :

The machine will have geared head with a hallow spindle. Mounted at each end antifriction bearing. The geared head have eight/spandle speeds and having hardended gears.

Feed Rolls :

Axial feed of power into the turning head is done with the help of feed rolls. The rotation of these rolls feed the bar into turning head with specified rate. the rotational speed of feed rolls is variable to suit the size of the bars. the drive is effected from a separate motor through V belts pulleys. The feeding rollers will be of high carbon High Carbon High chrome steel duly hardended.

Base :

The base of the machine will be rigid C.I. Casting on which the geared head and feed gear box assemblies are mounted.

Cutter head :

One set of cutter head is required to cover the complete range of sizes. The cutter head consists of one Tungsten Carbide button tool holder and three suitably profiled pressure rollers with one Tungsten Carbide guide. The adjustment is provided for setting the tools holder, pressure rolls and guide. The whole assembly is fixed to the hollow spindle. The cutter head can be easily removed & can set to cut different dia of the bars using a setting base.

Input & output Carriage :

For supporting and preventing the rotation of the bar one input & one output carriages are provided on either side of the machine. The carriages run on round bars of 15 ft. approximate both side of the machine.

Coolant System :

Constant flow of mineral based cutting oil is splattered on cutter head to cool the tool and rollers.

| Model | Motor for Cutting Head | Motor for Feeding gear Box | Coolant Pump Motor |

| TMT-CBP-45 | 10 HP/1440 RPM / 415V A.C | 02 HP/1440 RPM / 220V D.C | .25 HP/1440RPM / 415V A.C |

| TMT-CBP-75 | 25 HP/1440 RPM / 415V A.C | 03 HP/1440 RPM / 220V D.C | 01 HP/1440RPM / 415V A.C |

| TMT-CBP-140 | 40 HP/1440 RPM / 415V A.C | 10 HP/1440 RPM / 220V D.C | 02 HP/1440RPM / 415V A.C |