Company Information

Ask for more detail from the seller

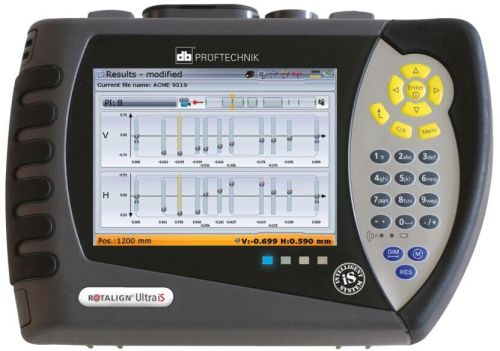

Contact SupplierReduce steam and gas turbine outage using laser alignment

Control sensor for automated compensation of potential laser drift

Measurement methods for true bore center and specific applications

Exclusive large bore brackets for tops-on and tops-off applications

Simple and quick measurement process up to 40 m (130’)

Powerful built-in splice function maximizes measurement flexibility and extends measurement range

Takes care of reference line position, rotor sag and thermal growths

Live Move function to monitor the alignment corrections in real time.

CENTRALIGN Ultra Expert has been specifically developed for the alignment of steam and gas turbines. The system is designed for the precise alignment of internal elements of rotating machines such as bearing rings, diaphragms, nozzles, inner shells and turbine casings.

The additional unique control sensor system monitors the laser drift, which automatically ensures the measurement accuracy over long distances and long measurement periods, when the laser stability is more subject to impacts by variations of air density and temperature. In combination with the highly precise and stable laser, the system delivers highest accuracy.

CENTRALIGN Ultra Expert saves extensive amounts of time and the effort needed in traditional methods to position the piano wire or barmeasurement shaft (arbor) into place and reposition it after each adjustment. The system calculates the center of each individual element and displays their locations, relative to each other on the screen. The desired centerline may be adjusted to determine the best-fit line and minimize corrections. Vertical and horizontal values or leftbottomright values can be preset.