Listing ID #3891996

Company Information

Ask for more detail from the seller

Contact SupplierENERAL

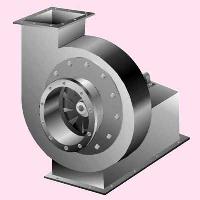

MESINA make Centrifugal Fans are known for their use in the VENTILATION & AIR CONDITIONING Field.

More than 500 such Fans are running in Industries to meet the requirement of Supply Air and Exhaust Air systems. These fans find usage in Steel Plants, Petro Chemical Industries, Textile Mills, Marine service on ships, Pneumatic conveying, Paper Mills, Potteries and scores of other Ventilation, Air conditioning and Air Washer applications in fast progressing Industrial World.

In Design, Development and Construction, emphasis has been placed on durability, reliability, continuous running, economy and quietness of operation.

Fan Classifications

There are mainly 3 types, Backward curve, Forward curve and Radial curve. Backward curve blades are usually specified in Supply Centrifugal Fans in Industries for Non-Overloading characteristic. Forward curve Fans are used in Air Handling units for greater air quantity at lesser speed while Radial blades are used in Centrifugal Exhaust Air Fans for high pressure.

Fan Construction

Fan Construction is as per Indian standards 4894-1987 and AMCA standards for Fan construction to withstand centrifugal force, torque, thrust, vibratory and critical speeds and to provide adequate strength to stationary and rotating parts.

Casings

Casings are volute design scroll welded on sides, supported on angle frames mounted on channel base frame. Fans are usually horizontal split casing type for removal of rotor wheel facility for servicing and replacement. For normal application casing thickness is 3.15mm whereas 4/6 mm is optional for special cases.

Rotors

Rotors also called impellers or wheels, they are fixed to HUB which are mounted on EN-8 shaft which is overhung on the extended shaft mounted on two bearings with pedestals. Arrangement -1 fans are generally single width single inlet only. All rotors are of welded construction and are balanced as per ISO-1940 Gr 6.3.

Blades

Blades are securely welded between extra thick Back Plate and Inlet Cone ring.

Bearings

Bearings are ball or roller type with grease lubrication equipped with pedestal for servicing.

Bearing Temp Limitation

Bearing Temp Limitation is 140° C for arrangement -1 and 90° C for arrangement - 3.

Special Fans

Spark resistant and high temperature construction fans are also available.

Fan Accessories

Fan Accessories that are available are Variable inlet vane damper, Outlet damper, Cushy foot mountings and Foundation bolts nuts.

Paint

Paint all fan parts except shaft and bearings are given a coat of Red Oxide and Epoxy Enamel paint.

Fan performance Requirements at site installation