Listing ID #6832088

Company Information

Ask for more detail from the seller

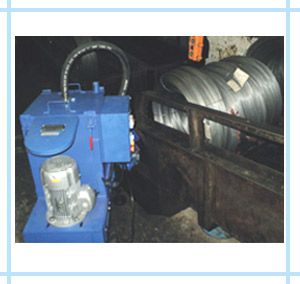

Contact Suppliercentrifugal filtration systems

A centrifugal filter replaces the gravitational force with the centrifugal force.

Centrifugal filtration is a form of the process known as sedimentation, the separation of particles that naturally occurs due to gravity. A centrifugal filter replaces the gravitational force with the centrifugal force, which can be thousands of times stronger than the latter. Simply put, centrifugal filtration increases the rate at which the natural process occurs. A centrifugal filter spins the lube oil at a high rotational speed and separates the particulate from the liquid. The centrifugal filter forces the heavier solids to the outside of the separator bowl producing a firm sludge cake.

The use of rotating machinery is necessary for almost every industry. Although this equipment is common in various applications, there are still a vast number of opportunities that can increase performance, reduce maintenance downtime and increase the life of such equipment—ranging from steam turbines and diesel engines to the use of pumps and actuators. Within many of these systems is a lubrication oil which can be beneficial or detrimental to how long such equipment will stay in service.

application

Honing

Super finishing

EDM applications

Advantages

Available in manual and automatic models

Provide extremely fine filtration

Options

Coolers

Magnetic separators

Salient Features :

No Filter Element

No Replacement Cost

Improved Product Finish

Reduced Oil Consumption

Extended Oil Change Period

Reduced Machine downtime

Reduced Storage & Disposal Cost of Waste Oil

Reduced Pollution and Environmental

Our company, Filters 23 India PVT LTD, located in Surendranagar (Gujarat), is a trusted organization that manufactures products like centrifugal filtration systems, compact band filters, coolant magnetic separators, coolant filter paper, etc. We, at Filters 23 India PVT LTD, are highly determined to our work and devoted to delivering the best value to our clients. By maintaining quality standards of the offered products and offering excellent customer service, we want to secure a distinct position in this field. We aim to gain the trust of numerous clients across domestic and overseas markets.

Fortunately, we are supported by a team of efficient & dynamic people who are very zealous and tackle all the troubles that come on their way in their daily activities in the company. They ensure the availability of adequate stock of every item all the time to cater to the rising market demands. Our professionals ensure that the right kind of raw material is procured from the vendors and used properly to manufacture the product range.

We have a state-of-the-art infrastructural base where all the processes including product development, quality testing, storing, packing, and distribution processes are carried out with ease. Our facilities are equipped with the latest technology, machines, and tools that facilitate our production rate. In addition to this, all new and innovative ideas & techniques are used for our whole business process.

Under the leadership of Mr. Dhruv, we are working to attain our business targets efficiently and carve a niche for ourselves in the market.