Company Information

Ask for more detail from the seller

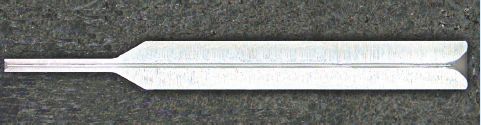

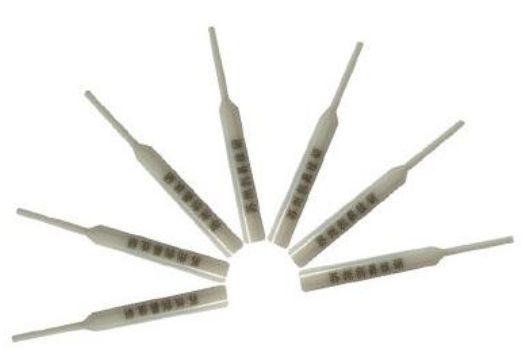

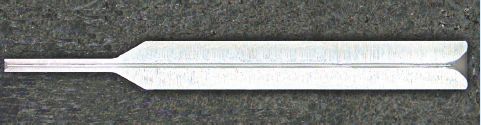

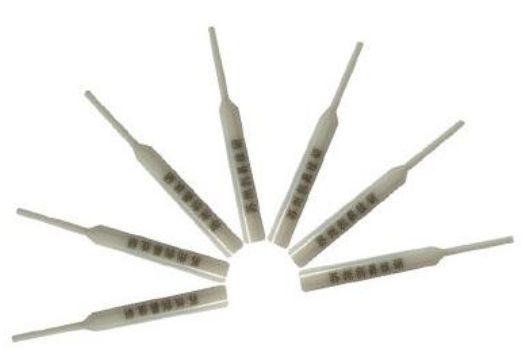

Contact SupplierThe Coil Winding Nozzle is a vital component for good quality coil winding. TROPHY’s ceramic nozzles are made for advanced coil winding requirements. They are excellent for high speed winding with high accuracy & minimizes stress to the wire.

Advantages :

TROPHY's ceramic nozzles are made for advanced coil winding requirements. They are excellent for the ultra-high speed winding with high accuracy requirements.

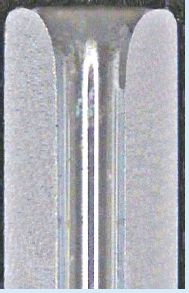

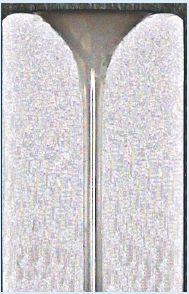

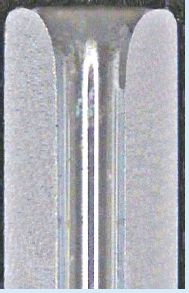

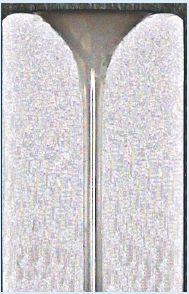

The CN series ceramic nozzles are made of Nano -zirconia material wth a material hardness of 1500HV and bending resistance up to 1700N/mm2. All radii are scientifically calculated and processed to ensure smooth travelling and minimal stress to the wire during ultra-high speed winding.

| Code | Model | D1 | d1 | L1 | D |

|---|---|---|---|---|---|

| CN 0.8 | CN0330-030-0807 | 0.8 | 0.3 | 7.0 | Φ3 |

| CN 1.0 | CN0430-030-1010 | 1.0 | 0.4 | 10.0 | Φ3 |

| CN 1.0 | CN0530-030-1010 | 1.0 | 0.5 | 10.0 | Φ3 |

| CN 1.4 | CN0730-030-1410 | 1.4 | 0.7 | 10.0 | Φ3 |

| CN 2.0 | CN0830-030-2014 | 2.0 | 0.8 | 14.0 | Φ |