Company Information

Ask for more detail from the seller

Contact SupplierApplications :

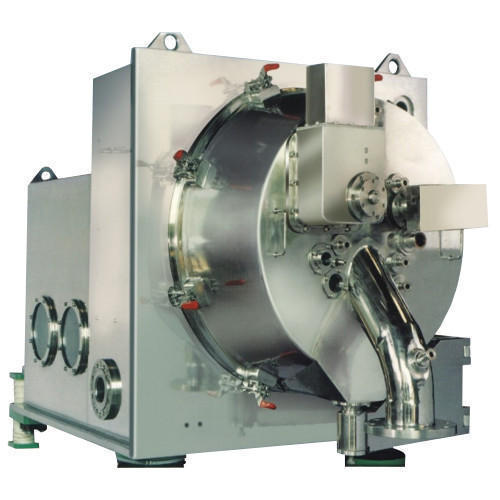

Horizontal peeler Centrifuges are successfully used in Food Stuff, Pharmaceutical, Plastic, Organic & Inorganic Chemicals Industry for separating solids from solid liquid slurry with 5 to 50% solids contents and particle size ranging from 2 microns to 10 mm. Products which are difficult to filter or decant can be easily separated using Peeler centrifuge.

Peeler Centrifuge is Used for :

AlumiAmino acids, benzoic acid, benzene, hexachloride, calcium hypo chloride hexachlorocyclohexane insulin, potassium bisulphate, sodium perborate, penicillin, sulphur, starch, etc.

Process

The unique feature of Horizontal Peeler Centrifuge is the constant basket speed i.e. all operations like feeding, drying discharging etc. are carried out at full-basket-speed. The sequence of Operations can be (either semi or fully automatically) controlled by Electro-hydraulic control panel / PLC controller

Typical Process Cycle

Design Features

Working Principle

Standard Machines : Contact parts in stainless steel / coated or contact parts with non-coatable parts in Hastelloy C Other materials on request.