Company Information

Ask for more detail from the seller

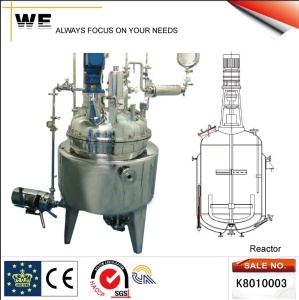

Contact SupplierWe are offering agitated reactors, chemical reactors etc.

main description:

1, the reactor is widely used in petroleum, chemical, rubber, pesticide, dye, medicine, food and scientific research sectors, to complete the curing, nitration, hydrogenation, alkylation, polymerization, condensation process, as well as organic dyes and intermediates, and many other processes.

2, the reactor is with jacket and agitator, and it can be generated by electricity, steam or heat transfer oil heating; the parts in connect with the raw material is in ocr18ni9 or 1cr18ni9ti anti-acid stainless steel.

3, the agitator of the reactor we made is including traditional oar type, turbine type, propeller type, anchor type, plate type, ribbon impeller, saw tooth disc type etc..

4, it is highly recommended for high shearing emulsifier reactor, combine plate type agitator, high shearing emulsifier and wall cleaner together.

main principle:

the working principle of the electric heating reactor is to put the electric heater into the heat transfer oil in the jacket, using the heat transfer oil as the heat carrier to heat the material in the reactor.

main features:

1, designed and produced as per customer's option from stainless steel reactor to kinds of non-standard chemical or light industry machineries.

2, due to different production technology & operation condition from different clients.

- the jacket heating including: electrical bar heating, steam heating and heat transfer oil heating.

-shaft seal device including: stuffing packing and mechanical sealing.

3, low noise, easy operation& clean, convenient for maintenance.

4, excellent in reacting effect, more appliance range.

5, electric appliance option: siemens, omron, schneider etc world famous brand.