Company Information

Ask for more detail from the seller

Contact Supplier

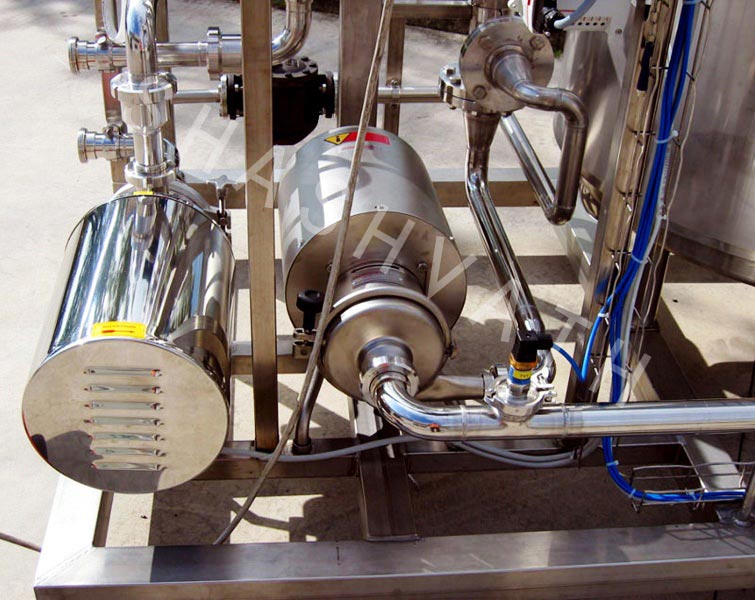

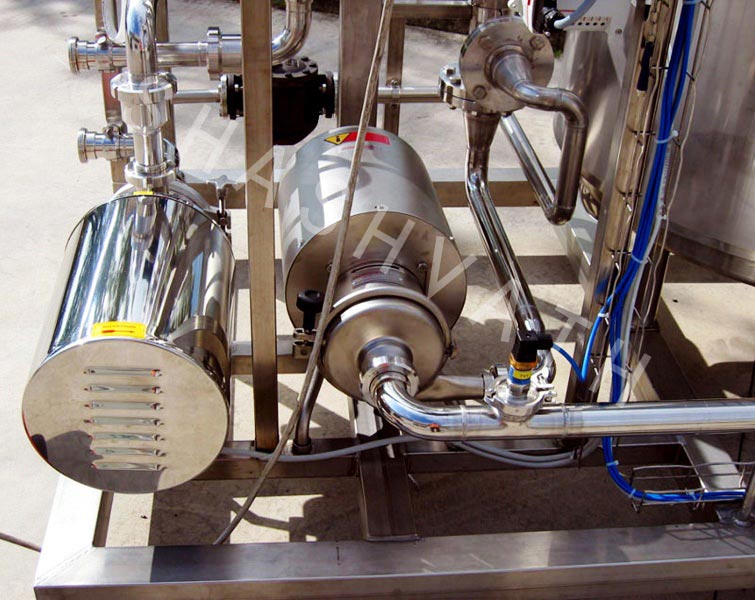

Clean-in-Place (CIP) is a method of cleaning the interior surfaces of pipes, vessels, process equipment, filters and associated fittings, without disassembly.The benefit to industries that use CIP is that the cleaning is faster, less labor intensive and more repeatable, and poses less of a chemical exposure risk to people. CIP started as a manual practice involving a balance tank, centrifugal pump, and connection to the system being cleaned.CIP has evolved to include fully automated systems with programmable logic controllers, multiple balance tanks, sensors, valves, heat exchangers, data acquisition and specially designed spray nozzle systems. Simple, manually operated CIP systems can still be found in use today.The Steam-In-Place (SIP) System is responsible for repeatedly steaming areas of product contact, including vessels, flow paths, and sample ports.This may be done to reduce the bio-burden on the system, or to kill harmful materials at the end of a batch.A typical SIP system will ensure that all areas being steamed have beenexposed to live steam for an adequate time to ensure the desired “kill”effect.The steam system must be able to measure and control steam temperature,pressure, and/or flow to ensure adequate steaming. Calculation of Fehrenheit or other measures is often required to meet process needs.

The advantages of this method are:

improved safety for workers involved in production of potential dangerous compounds,

faster cleaning,

reduced water usage,

less labor spending,

repeatable operations,

possibility to include a programmed cleaning cycle that is fully automated (employing PLC, sensors, valves) with recirculating detergent and rinse solutions.

Based on Time Action Flow Chemical Temperature cleaning cycle principles

Defined module and automation

Compliance to ISPE, ASME-BPE, cGMP guidelines

Easy to integrate with existing process system with all the essential analytical instruments

Custom designed as per process requirements

Cost and reliability gains from reduced manual work and reduced risk of accidental recontamination

Consistent cleaning efficiency with minimum CIP fluid requirements

Ensures efficient, automatic cleaning of process lines and vessels

Product Offerings:

CIP/SIP Docking System

One Tank CIP System

Multiple Tank CIP System

Mobile CIP recirculation & SIP trolley