Company Information

Ask for more detail from the seller

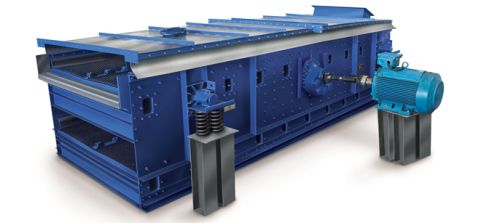

Contact Suppliersupport structure from vibrating masses and virtually noiseless operation.

The various versions of this type of Vibro Screens permit its use for wet and dry screening, coarse and fine separations and are widely used in steel mills, mineral beneficiation plants, chemical, mining, food and fertilizer industries, coal preparation plants and many others.

The main characteristic is OPERATIONAL RELIABILITY to suit the widest possible range of precise requirements.

The box shaped screen body can be fitted with almost any type of screen mat - of steel, rubber or plastic with provision for transverse, plane or longitudinal tensioning.

The steep angle of throw prevents mesh blinding, which permits maximum screening efficiency. The operating speed range normally varies between 1000 - 1500 rpm.

The screening machine is driven directly through a cardan shaft. The vibrating element is a through shaft, mounted in the two screen webs and fitted with unbalance segments. All clamping parts and screen mats are easily changed.

The design features high acceleration on the deck surface which permits handling of difficult-to-screen materials. The centrifugal force exciter unit is mounted on special vibration duty bearings that are grease lubricated and require minimum maintenance.

Available in single and double deck versions, the size range includes machines up to 2.5 m wide x 6.5 m long. Capacity range up to 1200 tons per hour depending upon separation size and material characteristics.