- Supply TypeManufacturer, Exporter, Supplier, Retailer

- Preferred Buyer Location All over the world

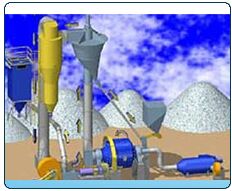

The efficiency of the early stages of grinding in a ball mill is much greater than that for formation of ultra-fine particles, so ball mills operate most efficiently by making a coarse product, the....

View More Details