Company Information

Ask for more detail from the seller

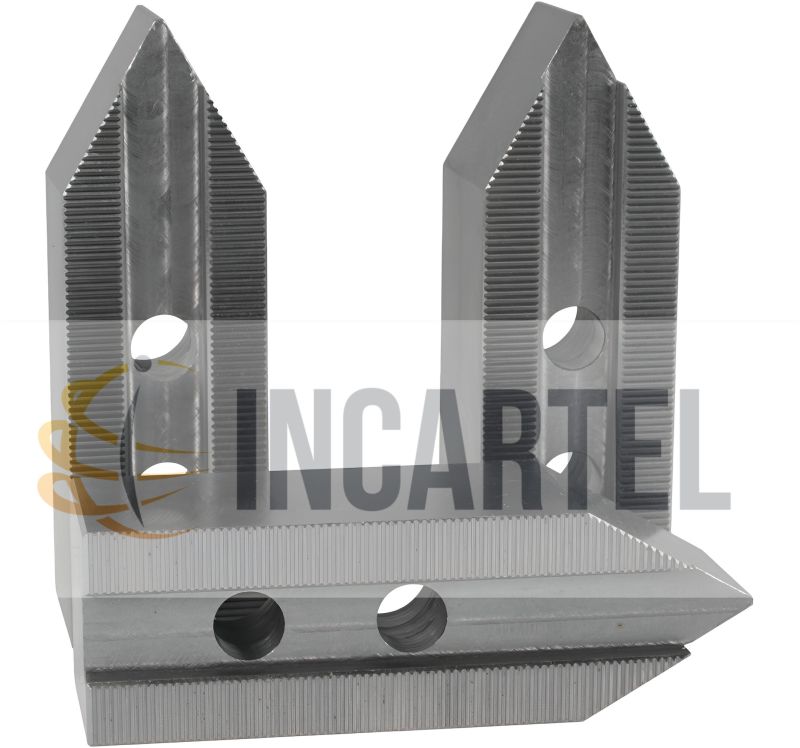

Contact SupplierCNC Soft Jaw – Description

CNC soft jaws are specialized workholding components used on CNC lathe and turning centers to securely grip finished or semi-finished workpieces without causing surface damage. Made from mild steel, aluminum, or other machinable materials, soft jaws are designed to be custom-machined to match the exact profile of the part being clamped. This ensures precision holding, reduces part slippage, and enhances repeatability during operations.

Key Features:

Material: Commonly made from mild steel, aluminum, or plastic (for delicate parts) to allow easy machining to custom contours.

Custom Machinability: Easily machined to conform to the workpiece shape, providing a snug and accurate fit for repeat operations.

Compatibility: Designed to fit a wide range of CNC chucks (2-jaw, 3-jaw, or 4-jaw), including power chucks and manual scroll chucks.

Protection: Prevents damage to finished or delicate surfaces, reducing scrap and rework.

Reusability: Can be re-bored or remachined multiple times for different components, increasing cost efficiency.

Accuracy: Enhances concentricity and grip precision, critical for tight-tolerance machining tasks.

Application: Ideal for second operations, internal gripping, and high-precision turning of complex profiles.

CNC soft jaws are essential for achieving high productivity, repeatability, and accuracy in modern machining environments.